Discover how recent advances in microfluidics technology are revolutionizing capillary flow in medical devices.

Understanding Capillary Flow in Medical Devices

Capillary flow plays a crucial role in the functioning of medical devices. It refers to the movement of fluids through small channels or capillaries due to the forces of surface tension and wettability. Understanding how capillary flow works is essential for designing effective medical devices that rely on this phenomenon.

In medical devices, capillary flow is often used for fluid transport, sample collection, and drug delivery. By harnessing the properties of capillary flow, medical devices can provide accurate and precise results, improve patient care, and enhance overall performance.

To fully comprehend capillary flow in medical devices, factors such as channel geometry, surface properties, and fluid viscosity must be considered. These factors influence the flow rate, direction, and behavior of fluids within the device, ultimately impacting its functionality.

By studying and analyzing capillary flow in medical devices, researchers and engineers can optimize design parameters, develop innovative solutions, and overcome challenges associated with fluid dynamics. This understanding paves the way for advancements in microfluidics, a field that has revolutionized capillary flow in medical devices.

Application of Microfluidics in Capillary Flow

Microfluidics has found numerous applications in capillary flow within medical devices. One prominent application is point-of-care diagnostics, where microfluidic devices enable rapid and accurate testing at the patient's bedside or in resource-limited settings.

For example, microfluidic platforms can be utilized for blood analysis, detecting biomarkers, and monitoring disease progression. These devices integrate sample preparation, analyte detection, and data analysis into a single compact system, facilitating real-time diagnosis and personalized treatment decisions.

Furthermore, microfluidics has revolutionized drug delivery systems by enabling precise control over dosage, release rate, and spatial distribution. By incorporating microfluidic channels and valves, medical devices can deliver therapeutics with high precision, minimizing side effects and improving patient outcomes.

In addition to diagnostics and drug delivery, microfluidics has applications in tissue engineering, organ-on-a-chip systems, and lab-on-a-chip technologies. These advancements in microfluidics have significantly improved the performance and capabilities of medical devices, opening up new possibilities in healthcare.

Benefits of Microfluidics in Medical Device Design

Moreover, the integration of microfluidics in medical device design not only enhances precision and reproducibility but also revolutionizes the way healthcare is delivered. By miniaturizing complex laboratory processes onto a single chip, microfluidic devices pave the way for personalized medicine and tailored treatment plans. This shift towards personalized healthcare not only improves patient outcomes but also reduces healthcare costs in the long run.

Additionally, the minimal sample and reagent volumes required by microfluidic devices not only reduce waste but also contribute to a more sustainable healthcare system. In a world where environmental sustainability is increasingly important, the eco-friendly nature of microfluidics aligns with the global push towards green technology and practices.

Lastly, the portability of microfluidic devices not only brings diagnostics closer to the patient but also empowers individuals to take control of their health. With point-of-care testing becoming more accessible, patients can receive immediate results and faster treatment, leading to improved health literacy and proactive healthcare management.

In conclusion, the incorporation of microfluidics in medical device design brings about a paradigm shift in healthcare, offering unparalleled accuracy, accessibility, cost-effectiveness, and patient-centered care. As technology continues to advance, the possibilities for innovation in medical devices are endless, promising a future where healthcare is not only effective but also truly patient-centric.

Example Use of Simulation for Design in a Blood Testing Microfluidic Device

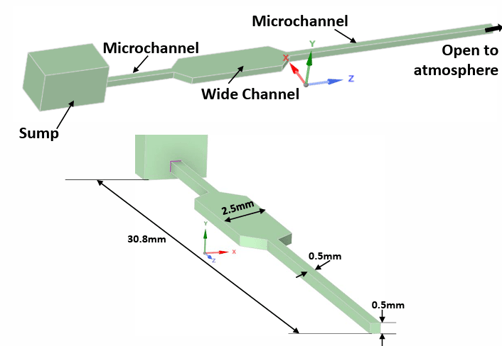

A blood testing microfluidic device generally consists of microchannels and a chamber where a drop of blood is placed for testing purposes (shown in Figure 1). The sample is collected in the collection reservoir called Sump. At the micro-scale, capillary force dominates, and the fluid displacement is directly related to the capillary flow. The filling process depends on several factors, such as material properties, geometry of the device, and fluid properties. Design and development of such consumables are time-consuming and expensive.

Figure 1: Fluidic pathways for a microfluidic device

In this example, a transient capillary flow simulation using ANSYS Fluent is developed using the volume of fluid (VOF) approach to account for water and air as the two phases. The model is based on the assumption that the sump/collection reservoir is filled with a sample. The wide microfluidic channel is connected to the chamber via a microchannel on one end, and on the other end, it is open to the atmosphere via a microchannel.

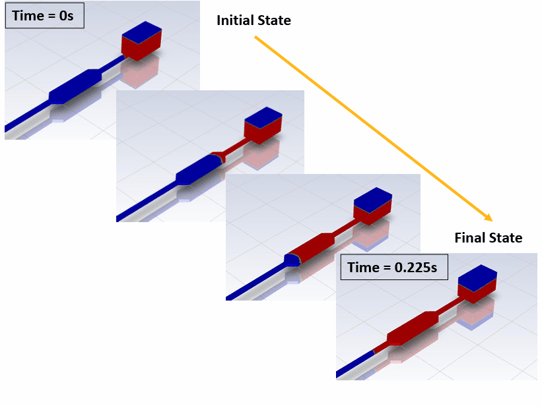

Figure 2: Transient Simulation Results: Filling of a Microfluidic Device

The transient simulation results for the filling of the microfluidic device are shown in Figure 2. The surface tension depends on the wall contact angle and the surface tension coefficient. The displacement can be altered by changing the fluidic pathways' material properties. Using modeling and simulation, we can investigate several design parameters such as contact angle, surface tension, and flow rates. Here is a video of how this model can be set up in ANSYS Fluent.

Figure 2 shows the results of the transient simulation for the microfluidic device's filling. The displacement can be altered by changing the material properties for the fluidic pathways, as the surface tension depends on the wall contact angle and the surface tension coefficient. Through modeling and simulation, we can explore various design parameters such as contact angle, surface tension, and flow rates. Click here to watch a video on how to set up this model in ANSYS Fluent.

In conclusion, the integration of microfluidics in medical device design has transformed capillary flow dynamics, enabling precise diagnostics, targeted drug delivery, and personalized healthcare solutions. By leveraging modeling and simulation tools, researchers and engineers can streamline the design process, reduce time-to-market, and enhance device performance. As we continue to push the boundaries of technology, the future of medical devices holds immense promise for revolutionizing patient care and advancing healthcare delivery. Explore the possibilities of microfluidics in medical device design further to unlock a world of innovation and improved healthcare outcomes.

Feb 9, 2024 2:25:09 PM