A gas turbine manufacturer needs to meet the basic goals below for a feasible combustor:

- Meet combustor performance and fuel efficiency targets.

- Mitigate emissions to meet regulatory standards.

- Ensure operability of combustor for fuel different blends.

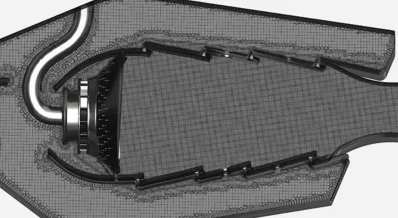

In order to design such a product, the design team may build numerous prototypes for testing. However, such tests are very costly. An efficient way to test the design variations are through the use of validated models. Our experts at Ozen have been involved in such simulations for the design of combustor systems and subcomponents.

A validated and useful computational model for combustor flow, thermal and emissions predictions require the following capabilities that are offered by Ansys:

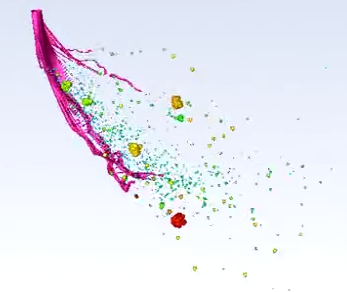

- Best-in-class tools for fuel and spray: Model Fuel Library, Chemkin-Pro and high-fidelity spray models.

- High-fidelity combustion and turbulence models.

- Parallel & automated meshing: to generate millions of high-quality poly-hexcore cells in minutes.

- High-performance Computing: Highly scalable computational fluid dynamics (CFD) solver.

Post by

Mert Berkman

Nov 29, 2023 2:49:49 PM

Nov 29, 2023 2:49:49 PM