Explore the innovative approach of using Computational Fluid Dynamics for designing packed distillation columns.

Understanding Packed Distillation Columns and Challenges

Packed distillation columns are commonly used in the chemical industry for separating mixtures into their individual components. These columns consist of a packed bed, which is filled with a packing material such as structured or random packing. The design and operation of packed distillation columns pose several challenges, including achieving efficient separation, minimizing pressure drop, and ensuring uniform liquid and vapor distribution.

One of the main challenges in designing packed distillation columns is achieving efficient separation. The goal is to maximize the contact between the liquid and vapor phases, allowing for effective mass transfer. This requires careful selection of the packing material and column dimensions to create a large interfacial area.

Another challenge is minimizing pressure drop across the column. As the liquid and vapor flow through the packed bed, frictional resistance can cause a significant pressure drop. This can affect the efficiency and performance of the distillation column. Designing the column with an appropriate packing material and optimizing the flow distribution can help reduce pressure drop.

Uniform liquid and vapor distribution is also crucial for the proper functioning of packed distillation columns. Uneven distribution can lead to maldistribution of components, reducing separation efficiency. Designing the column with appropriate distributors and ensuring proper liquid and vapor flow distribution can help achieve uniform distribution.

Overall, understanding the challenges associated with packed distillation columns is essential for designing efficient and reliable separation processes.

Key Steps in Designing a Packed Distillation Column with CFD

Designing a packed distillation column with CFD involves several key steps that ensure a successful design and efficient separation process.

1. Define the separation requirements: The first step is to define the desired separation performance, including the desired product purity and recovery. This will guide the design process and help determine the column dimensions, packing material, and operating conditions.

2. Select the packing material: The choice of packing material plays a crucial role in the separation efficiency. Different packing materials have varying surface areas and void fractions, which directly affect the mass transfer rates. Selecting the appropriate packing material based on the separation requirements is essential.

3. Create a 3D model of the column: Using CAD software, create a detailed 3D model of the packed distillation column. Include all the necessary components such as the packed bed, distributors, and feed location.

4. Define the operating conditions: Specify the operating conditions, including the feed flow rate, temperature, and pressure. These parameters will be used in the CFD simulations to analyze the flow behavior and separation performance.

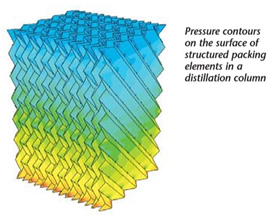

5. Perform CFD simulations: Use CFD software to simulate the fluid flow behavior inside the column. This includes analyzing the flow patterns, pressure distribution, and mass transfer rates. Based on the simulation results, make design modifications if necessary to improve the separation performance.

6. Evaluate the results: Analyze the simulation results to evaluate the separation performance. This includes assessing the product purity, recovery, and pressure drop. If the results meet the desired requirements, the design can be considered successful. Otherwise, iterate the design process to optimize the column performance.

By following these key steps, engineers can effectively design packed distillation columns using CFD and achieve efficient separation.

Ansys Capabilities

Ansys is a leading provider of engineering simulation software, including CFD tools for packed distillation column design. Ansys offers a range of capabilities that enable engineers to accurately model and simulate the fluid flow behavior inside the column.

One of the key capabilities of Ansys software is the ability to model complex geometries and packing materials. This allows engineers to create detailed 3D models of the packed distillation column, including the packed bed, distributors, and other components.

Ansys provides Euler multiphase framework with algebraic interfacial area density (AIAD) model, advanced turbulence models, evaporation and condensation models, and multiphase flow models that accurately capture the flow behavior inside the column. These models take into account the interfacial area, mass transfer rates, and pressure drop, providing engineers with a comprehensive understanding of the separation process.

Furthermore, Ansys software offers post-processing tools that enable engineers to analyze and visualize the simulation results. This includes generating flow visualization, gas holdup distribution, entrainment and absorption prediction, pressure and residence time distribution, and dissolution mass transfer rate prediction.

Overall, Ansys provides engineers with the necessary tools and capabilities to design packed distillation columns using CFD and optimize the separation performance.

Case Studies and Applications

There have been several case studies and applications of using CFD for packed distillation column design in various industries.

One case study involved the design of a packed distillation column for the separation of a binary mixture in the pharmaceutical industry. By using CFD simulations, engineers were able to optimize the column design, resulting in improved separation efficiency and reduced costs.

In another application, CFD was used to design a packed distillation column for the separation of ethanol-water mixtures in the biofuel industry. The simulations helped in identifying areas of high pressure drop and maldistribution, leading to design modifications that enhanced the separation performance.

These case studies and applications demonstrate the effectiveness of using CFD for packed distillation column design in various industries. By leveraging the power of CFD, engineers can achieve efficient separation, reduce costs, and improve overall process performance.

Tags:

Mar 13, 2024 11:33:01 AM