Discover the significance of maintaining clean industrial tanks and how simulation can aid in predicting the cleaning process.

Maintaining Clean Industrial Tanks: advantages

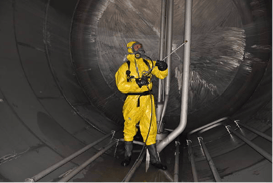

Maintaining clean industrial tanks is crucial for several reasons. Firstly, it ensures the safety of workers and the environment. Contaminated tanks can pose serious health risks and may lead to environmental pollution if not properly cleaned. Regular inspections help comply with environmental regulations and ensure the mitigation of the risk of accidents and chemical spills.

Secondly, clean tanks contribute to the efficient operation of industrial processes. The build-up of sludge, sediment, or other contaminants can hinder tank performance, resulting in decreased productivity and increased energy consumption. Regular cleaning helps maintaining the optimal functioning of tanks, ensuring smooth operations and minimizing downtime, especially when different products are stored periodically.

Furthermore, maintaining clean industrial tanks prolongs their lifespan. Corrosion and sediment accumulation can cause damage to tank structures over time. Regularly cleaning the tanks addresses these issues, preventing costly repairs or premature tank replacement. This not only saves money but also ensures the longevity and reliability of the tanks.

CFD Simulation applied to the cleaning process

Computational Fluid Dynamics (CFD) simulation allows engineers to model and analyze fluid flow, heat transfer, and chemical reactions within the tank, as well as the cleaning process. It offers valuable insights and optimization opportunities leading to better maintenance outcomes.

By using CFD, engineers can assess the effectiveness of different cleaning methods and equipment, such as high-pressure water jets. Optimization allows for minimizing cleaning time, agent/water use, and power consumption. Single and multiphase modeling capabilities provide insights into the time required to complete the task and a better understanding of the effects of nozzle design and configuration.

While there are first principles that can be followed, the large diversity of tanks, shapes/sizes, and internal structures makes 'validation' a very time-consuming task. In many cases, real-size testing is required, which takes a considerable amount of time. Well-established simulations can expedite the process, as demonstrated in the video below. Note that a water jet is rotating to cover all the internal areas, which are monitored over time.

Summary

Maintaining clean industrial tanks is essential for safety, efficiency, and longevity. Regular cleaning reduces the risk of accidents, ensures optimal tank performance, and prevents structural damage. Furthermore, CFD simulation provides valuable insights into the cleaning process, allowing for optimization and improved outcomes.

By choosing the right industrial tank cleaning service and utilizing advanced techniques such as CFD simulation, industries can ensure the cleanliness and reliability of their tanks, contributing to a safer and more efficient working environment. Each industrial tank has unique characteristics and cleaning requirements. CFD simulations can help assess aspects such as,

- Effect of nozzle/spray head selection

- Cleaning impact pressure and shear force

- Time for complete cleaning

- Liquid consumption

- Film coverage

Tags:

Jan 24, 2024 10:11:54 AM