Engineering challenges in the automotive industry and the solutions that Ansys and Ozen Engineering offer.

Understanding the Concept of Structural Integrity in Vehicle Engineering

Structural integrity is a critical aspect in vehicle engineering as it ensures the safety and durability of vehicles. It refers to the ability of a vehicle's structure to withstand various forces and loads without experiencing failure or deformation. This includes withstanding the forces during acceleration, braking, cornering, and other dynamic movements.

Challenges in Vehicle Engineering:

-

Structural Performance, Weight, and Cost One of the intricate challenges faced by vehicle engineers is striking the right balance between structural performance, weight considerations, and cost-effectiveness. Achieving this delicate equilibrium requires a precise approach in the design and engineering processes.

-

Material for a Vehicle's Lifespan Selecting the right materials that can withstand the test of time is a pivotal consideration in vehicle engineering. The chosen materials must not only ensure safety but also contribute to the life and reliability of the vehicle throughout its lifecycle.

-

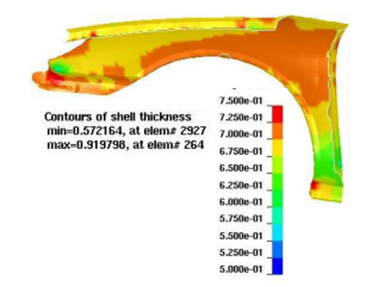

Forming Complex Body Panels Building a vehicle's structure involves more than meets the eye. The process of forming complex body panels adds another layer of challenge to the mix. Vehicle engineers must navigate this complexity to ensure not only aesthetic appeal but also structural soundness.

To achieve structural integrity, vehicle engineers must consider factors such as material selection, design optimization, and simulation analysis. Moreover, structural integrity plays a vital role in the overall performance and efficiency of vehicles. A well-designed and structurally sound vehicle can provide better handling, stability, and fuel efficiency. It also contributes to reducing vibrations, noise, and harshness, providing a more comfortable and enjoyable driving experience.

Advantages of Ansys Simulation in Structural Integrity of Vehicles

Ansys simulation tools offer numerous advantages in analyzing and ensuring the structural integrity of vehicles. These tools allow engineers to perform virtual testing and analysis, reducing the need for physical prototypes and costly experimental tests.

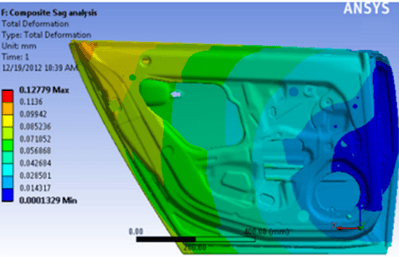

Accurate Predictions : Ansys simulation excels in accurately predicting the behavior and performance of vehicle structures under diverse loads and conditions. Engineers can simulate various scenarios, unveiling potential weaknesses and areas for enhancement without the need for extensive physical testing.

Optimizing Design and Materials: One major advantage lies in the ability to optimize vehicle design and materials. Engineers can explore different design options, assessing their impact on structural integrity. This empowers the development of vehicles that are not only lighter but also more efficient and safer.

Realistic Simulation of Operating Conditions: Ansys simulation goes beyond the theoretical, simulating real-world operating conditions and environmental factors. From temperature and humidity to vibrations and external forces, engineers can evaluate the impact on structural integrity, ensuring vehicles are robust in any situation.

Ansys Capabilities at a Glance:

- Accuracy: Implicit/explicit solvers and detailed material models, including composites. Fluid–structure interaction (FSI) for realistic loading.

- Optimization & AM: Design of Experiments (DOE) and topology optimization with design-to-print additive manufacturing workflows.

- Material Management: Intelligent materials selection and management for a holistic engineering approach.

Ozen Engineering Experience with Structural Integrity in Vehicle Engineering

Specializing in vehicle engineering structural integrity analysis, Ozen Engineering is a top supplier of engineering simulation services. Ozen Engineering has years of experience in the automotive sector and has assisted several clients in enhancing the structural integrity of their cars.

We are aware of the particular difficulties the automobile sector faces, such as the demand for lightweight materials, increased safety, and increased fuel economy. We collaborate closely with our customers to create creative solutions that deal with these issues and guarantee the cars' structural integrity.

In addition to structural integrity analysis, We offer other engineering simulation services such as crash analysis, durability analysis, and fluid dynamics analysis. Our expertise and advanced simulation capabilities make us a trusted partner for vehicle engineering projects.

Tags:

Mechanical, FEA, Static Structural, Structural Analysis, Vehicle Engineering, lightweight design, Automotive EngineeringNov 30, 2023 1:13:48 PM