A digital twin is a virtual model which represents a physical object and updates in real time. This connection uses data from sensors on the physical object.

This real-time link transforms the model. It becomes more than a static simulation. It becomes a live communication bridge between the physical asset and the engineer. Data flows in both directions, enabling a continuous dialogue that translates raw sensor readings into actionable engineering knowledge.

This blog explores this technology using a magnetic coil as a simple example to help clarify complex ideas. We will explore what digital twins are, how they are built, and why they are valuable.

Understanding the Digital Twin

What is a Digital Twin?

A digital twin is a live, virtual replica. It mirrors a real-world system or asset. This asset could be a single component. It could also be an entire factory or power plant.

The twin is synchronized with the physical asset. This synchronization happens at a specified frequency. This ensures the virtual model accurately reflects the real world at all times.

Sensors on the physical asset collect data. This data can include temperature, pressure, or electrical current. The data continuously feeds the virtual model. This process keeps the twin accurate and up-to-date.

The Value of a Digital Twin

Digital twins provide deep operational insight. They show what is happening inside an asset in real time. This allows for continuous system analysis and performance monitoring.

This insight enables predictive maintenance. Companies can anticipate issues before they happen. This capability prevents costly, unplanned downtime. Engineers also use twins to optimize performance. They can test different operating scenarios virtually and safely. This optimization leads to greater efficiency and lower operating costs.

This continuous stream of operational data creates a fundamental shift. Traditional engineering often focuses on designing a product that works correctly at launch. The design phase largely concludes when the product ships. A digital twin, however, experiences the entire life of the asset alongside its physical counterpart. It gathers data on actual use, wear patterns, and performance in varied environments. This information creates a powerful feedback loop, where insights from the operating twin of one product generation directly inform the design of the next. The engineering focus moves from a single launch to the entire product lifecycle. This creates a compounding knowledge advantage for an organization.

Ansys Twin Builder

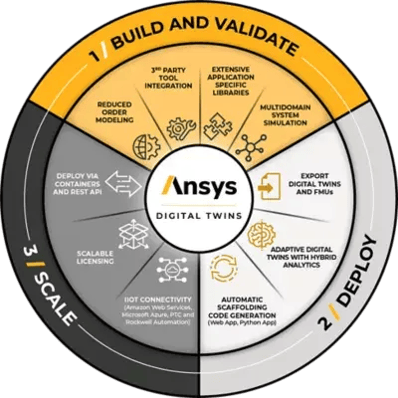

Ansys Twin Builder is a software platform. It allows engineers to create digital twins. The platform is an open solution. It connects to many different tools and data sources.

Twin Builder integrates multiple model types. It combines detailed 3D physics models, broader system models, and embedded software into one environment. It supports industry standards like the Functional Mock-up Interface (FMI) for seamless tool integration.

The platform manages the entire twin creation process. Engineers build, validate, and deploy twins using Twin Builder. This structured workflow can cut the time needed to create an accurate model in half. It also provides tools to connect the finished twin to Industrial Internet of Things (IIoT) platforms for live operation.

The platform's value extends beyond just creating twins. It also makes the technology more accessible. Building a complex system model traditionally required deep expertise in programming and multiple simulation domains. Twin Builder features a "low-code" interface, wizard-driven editors, and extensive libraries of pre-built components. These features lower the barrier to entry. They allow engineers with little to no programming background to create sophisticated digital twins. This democratization of technology enables domain experts to focus on solving the engineering problem, not the software problem.

Reduced-Order Models (ROMs)

Making Complex Physics Fast: What is a ROM?

Full 3D physics simulations are very accurate. They model complex phenomena like fluid flow, structural stress, or electromagnetics. However, these simulations are computationally expensive. A single analysis can take hours or even days to complete.

Digital twins need real-time results. They must respond instantly to changes in the physical world. They cannot wait hours for an update from a simulation. This speed requirement creates a significant technical challenge.

A Reduced-Order Model (ROM) is the solution. A ROM is a highly accurate simplification of a complex model. It captures the essential behavior of the full physics simulation. It produces results in seconds or less, using minimal computational resources.

From Hours to Seconds: How ROMs are Made

The creation of a ROM follows a structured process. Engineers first build a high-fidelity 3D model. For our coil example, this would be a detailed magnetostatic simulation in Ansys Maxwell.

They then run many simulations with this model. This process is called a Design of Experiments (DOE). The DOE systematically tests a wide range of input values. For the coil, this would mean simulating the magnetic field for many different current levels.

The results of these simulations "train" the ROM. The ROM uses advanced mathematical algorithms to learn the relationship between the inputs and the outputs. This process creates a compact, efficient, and accurate mathematical representation of the underlying physics. The final ROM can be exported and used in other tools like Ansys Twin Builder. The ROM acts as a fast and reliable substitute for the full 3D model.

Dynamic ROMs: Modeling Systems in Motion

Some systems have static behavior. Their output depends only on the current input value. A standard ROM, often based on a response surface, works well for these cases.

Most real-world assets are dynamic. Their behavior changes over time. Their outputs depend on a history of inputs, not just the present state. A motor's temperature, for example, depends on how long it has been running and at what load.

A Dynamic ROM is needed for these systems. It is specifically designed for transient, nonlinear problems. A Dynamic ROM accepts inputs that change over time. It predicts how the system's outputs will evolve over time in response. This capability is essential for creating a true digital twin that mirrors a live, operating asset.

This process represents a fundamental shift in how simulation provides value. Traditionally, the output of a simulation is a data file or a static report. A ROM, however, is an executable model. It can be packaged as a standard, self-contained component, such as a Functional Mock-up Unit (FMU). This transforms the simulation result from a piece of data into a functional, "plug-and-play" building block. A supplier can deliver a ROM of their component, which an OEM can then integrate directly into a larger system simulation. This modularity makes ROMs a distributable, functional asset that also protects a company's intellectual property by acting as a "black box".

An Example Solenoid Coil

The Physical Setup

This example uses a straightforward physical setup consisting of a magnetic solenoid coil and a power supply which sends an electrical current through the coil. Solenoid coils are electromagnetic devices essential to many sectors and applications, from industrial automation to consumer electronics. Serving as the heart of solenoid actuators, their chief role is to enable automatic switching, locking, or movement of various parts within electrical and mechanical systems.

When an electric current passes through the solenoid coil, it creates a magnetic field that can be used to move an armature which activates or controls an attached device. A physical sensor is placed near the coil to measure the strength of this magnetic field. An operator can manually adjust the current level on the power supply to change the magnetic field in the real world.

Building the Coil's Digital Twin

The coil's digital twin is created in Ansys Twin Builder. The project contains several key blocks. These blocks work together to form the complete twin.

One key block is the Data Connector. This block is the twin's link to reality. It reads the live current value directly from the power supply. A simple Python script often facilitates this communication, acting as a digital wire between the physical hardware and the virtual model.

The most critical block is the Dynamic ROM. This block represents the coil's physics. It was created from a detailed Ansys Maxwell magnetostatic simulation.

Creating a dynamic ROM involves three main stages: creating the high-fidelity model, generating training data, and building the ROM.

1. Create the High-Fidelity Physics Model in Ansys Maxwell

The first step is to build a detailed and accurate virtual representation of the physical component. For the magnetic coil example, this is done in Ansys Maxwell, a software designed for low-frequency electromagnetic analysis.

-

Modeling: Engineers create the 3D geometry of the coil. They assign material properties, such as defining the coil as copper and specifying properties for any surrounding components.

-

Physics Setup: They define the physics of the problem. This includes setting the solver type (e.g., Magnetostatic for steady currents or Transient for time-varying fields) and applying excitations, such as the electrical current flowing through the coil.

-

Solving: Maxwell then solves Maxwell's equations for this detailed model to accurately calculate the resulting magnetic field. This initial model is often called the Full-Order Model (FOM). It is highly accurate but can take hours to solve for a single scenario.

2. Generate Training Data with Parametric Analysis

The next step is to "train" the ROM by showing it how the high-fidelity model behaves across its entire operating range. This is done by running the Maxwell simulation many times with different inputs.

-

Define Parameters: Engineers identify the key input variables that will change during operation. For the coil, the primary input is the current. For more complex systems, there could be multiple inputs like voltage, temperature, or physical position.

-

Run Parametric Sweeps: Using a tool like Ansys Optimetrics, they perform a parametric sweep, also known as a Design of Experiments (DOE). The software automatically runs the Maxwell simulation for a wide range of the defined input values (e.g., simulating the coil at 1A, 2A, 3A, and so on).

-

Collect Snapshots: Each simulation run produces a "snapshot" of the results, linking specific inputs to their corresponding outputs (e.g., Input Current = 1A, Output B-Field = 1.4 mT). For a Dynamic ROM, these snapshots are collected from transient simulations, capturing how the system's outputs change over time in response to time-varying inputs. This collection of input-output data serves as the training data for the ROM.

3. Build and Export the Dynamic ROM in Ansys Twin Builder

The final stage uses the generated training data to build the fast, lightweight ROM.

-

Import Data: The training data from the Maxwell parametric sweeps is brought into Ansys Twin Builder.

-

Train the ROM: Twin Builder's ROM builder uses advanced mathematical algorithms and machine learning techniques, sometimes including artificial neural networks, to analyze the training data. It learns the precise relationship between the inputs and outputs, creating a compact mathematical model that accurately represents the complex physics of the original Maxwell simulation.

-

Validate and Export: The created ROM is validated to ensure its predictions are accurate, often within a small percentage of the full 3D simulation's results. Once validated, the ROM is exported as a self-contained, portable component, typically in the Functional Mock-up Unit (FMU) format. This FMU is the final block that is used in the digital twin system model, ready to provide near-instantaneous results.

This example ROM takes the live current value from the Data Connector as an input. It then outputs a predicted magnetic field (B-field) value.

Putting the Twin to Work

The live demonstration shows the twin in action. An operator increases the current on the power supply. The Data Connector reads this new value instantly and sends it to the twin.

This live current data flows into the Dynamic ROM. The ROM immediately calculates the new B-field strength based on the physics it learned during its creation. The twin's prediction then appears on the screen.

The result validates the twin's accuracy. The demo shows the physical sensor reading a magnetic field of 4.63 mT. The twin's output simultaneously shows a predicted value of 4.6mT. This one-to-one match between the physical measurement and the virtual prediction proves the twin is working correctly.

From a Solenoid Coil to Complex Systems

Why This Example Matters

A digital twin for a single coil may seem excessive since the physics are relatively simple and well-understood. However, the purpose of this example is not to solve a simple problem but to demonstrate a powerful and repeatable method.

The workflow is the key takeaway. First, we model complex physics in a high-fidelity tool. Second, we reduce that model to a fast and accurate ROM. Third, we connect that ROM to real-world data in a system-level environment. This process is highly scalable.

Scaling Up the Concept

Now consider a complex industrial asset. A modern wind turbine or a commercial jet engine are good examples. These are incredibly complex systems. They involve the interaction of aerodynamics, structural mechanics, thermal effects, electronics, and control systems.

Simulating one of these entire systems with full 3D physics in real time is impossible since the computational complexity is far too high. Furthermore, these industrial systems operate in unpredictable environments. They experience complex interactions between many different components, which adds to the challenge.

The Power of a Scalable Method

The method demonstrated with the coil solves this complexity problem. Engineers can model each major component of a larger system separately. They create a ROM for the generator, another for the gearbox, and another for the turbine blades of a wind turbine.

Each ROM is a fast, accurate, and validated model of its specific component. It acts as a "black box" that perfectly encapsulates that component's physical behavior. Ansys Twin Builder then assembles these individual ROMs. It connects them into a complete, multi-domain system model that represents the entire asset.

This modular approach makes the impossible, possible. It allows for real-time performance analysis and prediction for entire, complex industrial assets. The simple coil demo teaches the exact method needed to tackle these massive challenges. This methodology elevates industrial data from a passive, historical record into an active, predictive asset. By fusing real-time sensor data with predictive physics models, the digital twin unlocks the forward-looking value dormant in the massive data streams generated by modern industry.

Conclusion

Digital twins are live virtual models. They are connected to physical assets through real-time data. This connection provides a constant stream of information about an asset's performance and health.

Reduced-Order Models make this technology practical. ROMs provide the incredible speed needed for real-time simulation without sacrificing the accuracy of detailed physics. This combination of accuracy and speed is the core technical enabler of the digital twin.

This technology gives engineers powerful new insight. They can monitor, predict, and optimize asset performance throughout its entire lifecycle. This capability represents a fundamental and valuable shift in engineering practice.

Ozen Engineering Expertise

Ozen Engineering Inc. leverages its extensive consulting expertise in CFD, FEA, optics, photonics, and electromagnetic simulations to achieve exceptional results across various engineering projects, addressing complex challenges such as antenna design, signal integrity, electromagnetic interference (EMI), and electric motor analysis using Ansys software.

We offer support, mentoring, and consulting services to enhance the performance and reliability of your electronics systems. Trust our proven track record to accelerate projects, optimize performance, and deliver high-quality, cost-effective results. For more information, please visit https://ozeninc.com.

If you want to learn more about our consulting services, please visit: https://www.ozeninc.com/consulting/

CFD: https://www.ozeninc.com/consulting/cfd-consulting/

FEA: https://www.ozeninc.com/consulting/fea-consulting/

Optics: https://www.ozeninc.com/consulting/optics-photonics/

Photonics: https://www.ozeninc.com/consulting/optics-photonics/

Electromagnetic Simulations: https://www.ozeninc.com/consulting/electromagnetic-consulting/

Thermal Analysis & Electronics Cooling: https://www.ozeninc.com/consulting/thermal-engineering-electronics-cooling/

Other useful resources:

Digital Twin - Ansys Twin BuilderHow to Create a Digital Twin of the Golden Gate Bridge

Jul 21, 2025 4:01:11 PM