SUMMARY

For users of Ansys Mechanical, expanding into Ansys Motion can unlock powerful new capabilities—but making that transition requires more than just navigating a familiar interface. While both tools share the same graphical environment, they rely on fundamentally different solvers and modeling approaches. Understanding these conceptual differences is essential for leveraging Ansys Motion effectively and avoiding common pitfalls. Whether you're looking to broaden your simulation scope or enhance your current workflows, recognizing where Mechanical ends and Motion begins is key to a successful and efficient integration. In this blog, we'll explore these critical distinctions to help Mechanical users confidently step into the world of multibody dynamics.

In this blog, we’re not focusing on specific setup details. Instead, the goal is to highlight the broader workflow differences between Ansys Mechanical and Ansys Motion. While both tools are part of the same simulation ecosystem, they are built on different modeling philosophies. This means that to use Ansys Motion effectively, Mechanical users must adapt their typical approach. We'll explore key concepts and adjustments that are essential for successfully transitioning workflows and fully leveraging the capabilities of Ansys Motion.

Unique characteristics of Motion setup

Thinking in the way things are defined in Motion, is possible to identify two main differences respect to Mechanical:

- Grouped property definitions: In Motion, is possible to define properties for several similar objects using an independent Properties object that applies to the entire group. The objective here is to avoid to define equal values for each individual objects. Imagine a model with dozens of contacts and you need to define similar friction properties for each one of them. If you were working on Mechanical, you will need to define the friction coefficient on each contact properties section. In Motion, by creating one contact properties object you can point all the desired contact pairs defining the values once.

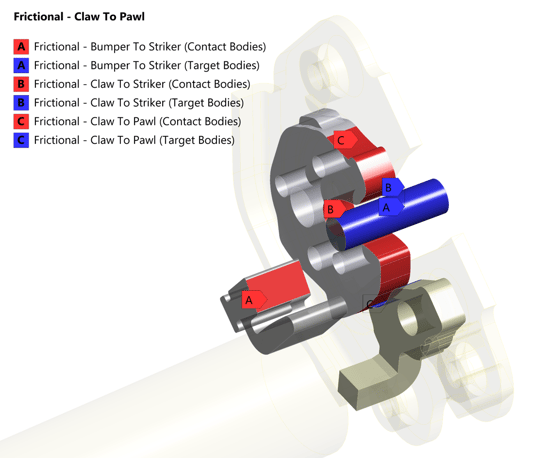

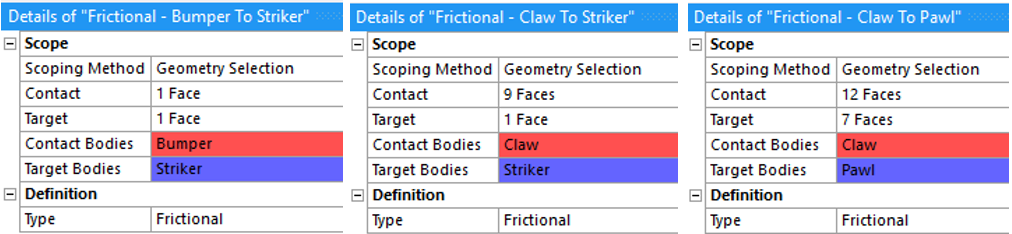

In this example, we can see a model with three contacts defined to consider the interaction between several parts. In this setup there are two Motion objects intended to define the numerical and friction properties. Compared to Mechanical, complete definition would be necessary in each contact object.

Contact definition:

Contact properties object: Note the scope is a list including the three defined contact objects.

Contact Friction properties:

- Use of functions: The second major difference is the way to create functions. In Mechanical you can define some basic functions directly on the object (for example to define a time variable force). In Motion, the Sub-Entity menu allows to create more advanced functions. A more detailed explanation of the available function can be found in Ansys help: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v251/en/motion_ug/motion_ug_using_motionfeat.html

Continuing with the example, using the 'Function Expression' object two functions were created. The first to define a rotational displacement for a joint. The second function calculates the reaction torque on a revolution joint.

Function expression: STEP. This function creates a smooth transition between a minimum and a maximum value during two 'time' points. Our function is intended to define rotation, that is why we convert the final argument to radians using the DTOR constant.

Function expression: TZ. This function calculates the torque on a rotational joint named RJ_01. It uses two arguments called p1 and p2. They are markers created automatically on the joint.

- Nested definitions: As you can imagine, the independent objects previously defined need to be assembled somehow to complete the setup. In the example model, the friction coefficient is not constant. A spline is created to define the variation of this coefficient with relative speed. Then, we need a Spline object to be used in the Contact Friction properties object and this object is used to define contacts behavior. The logic is the same even if we don't need a specific connection between objects.

CONCLUSION

- Ansys Motion uses the same preprocessing features as a standard Mechanical simulation: geometry, connections, contact and meshing.

- There are some specific features for Ansys Motion for: body properties and markers, contact properties, special joint boundary conditions and forces, variable expressions, co-simulation buttons, export files and run the Ansys Motion post processer.

Downloadable Resources

Ozen Engineering Expertise

Ozen leverages its extensive consulting expertise in CFD, FEA, optics, photonics, and electromagnetic simulations to achieve exceptional results across various engineering projects, addressing complex challenges like multiphase flows, erosion modeling, and channel flows using Ansys software.

Ozen leverages its extensive consulting expertise in CFD, FEA, optics, photonics, and electromagnetic simulations to achieve exceptional results across various engineering projects, addressing complex challenges like multiphase flows, erosion modeling, and channel flows using Ansys software.

We offer support, mentoring, and consulting services to enhance the performance and reliability of your hydraulic systems. Trust our proven track record to accelerate projects, optimize performance, and deliver high-quality, cost-effective results for both new and existing water control systems. For more information, please visit https://ozeninc.com.

Tags:

Ansys Motion, rigid body dynamics, Structural Analysis, ANSYS Mechanical, Setup Productivity, 2025 R1May 22, 2025 12:24:26 PM