Challenges in EV Battery Design

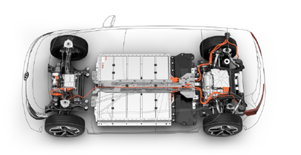

Propelled by the recent tech advancements and shifting consumer demands, electric vehicles (EVs) are at the forefront of a dynamic transformation as automakers vie to meet emerging opportunities head-on, navigating engineering challenges into innovative opportunities.

The growing market demand is led by a strong focus on efficiency, reliability, affordability, and environmental sustainability. Plus, the potential for industry-wide disruptive innovation regularly attracts new market entrants, such as Rolls-Royce, which is keen to outpace Tesla and spearhead the next generation of luxury EVs.

At the heart of the EV evolution is battery optimization. Optimizing battery performance is crucial for EVs to compete with internal combustion engine vehicles, given it directly impacts their range, lifespan, charging time, safety and overall performance.

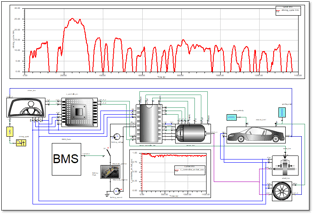

Electro-Thermal Coupled (ETC) analyses are critical in optimizing battery performance and can be categorized into two types: battery thermal management analysis and system applications analysis. Reduced-order modeling (ROM) is a methodology used within system applications analysis for faster and more accurate results.

Battery Thermal Management Solutions

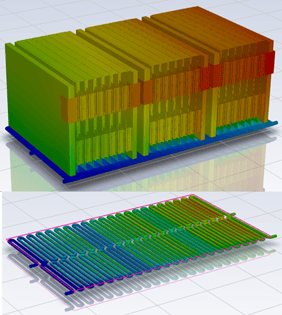

Battery thermal management analysis is a crucial aspect of the overall design of electric vehicle (EV) batteries. It involves the study and optimization of temperature distribution and cooling systems within battery packs.

Battery thermal management is important for several reasons:

- Optimizing Performance: Temperature significantly affects battery performance, including its capacity, power output, and lifespan. By analyzing and managing thermal conditions, battery designers can optimize performance and ensure efficient operation.

- Enhancing Safety: Maintaining appropriate temperature levels is essential for safe battery operation. Excessive heat can lead to thermal runaway, resulting in battery degradation, reduced lifespan, or even safety hazards like fires or explosions. Effective thermal management helps mitigate these risks.

- Improving Efficiency: Managing battery temperature improves overall system efficiency. Cooling or heating the battery to the optimal operating temperature range reduces energy losses and enhances energy conversion efficiency.

- Extending Battery Life: Excessive temperatures, both high and low, can accelerate battery degradation. By controlling temperature variations and maintaining the battery within an optimal temperature range, the lifespan of the battery can be prolonged.

- Optimizing Range: Temperature impacts the range of an electric vehicle. Cold temperatures can decrease battery capacity, while high temperatures can lead to increased internal resistance. By managing battery temperature, designers can optimize the vehicle's range.

Ansys provides a powerful toolset for developing Reduced Order Models (ROMs), which offer a simplified way to understand complex systems. These models are highly valuable for battery thermal management analysis as they can be run rapidly, providing real-time or near real-time insights into battery behavior.

1. Performance Optimization

![]() Ansys Fluent and Twin Builder are used to improve battery performance through accurate temperature distribution modeling and battery equivalent circuit modeling.

Ansys Fluent and Twin Builder are used to improve battery performance through accurate temperature distribution modeling and battery equivalent circuit modeling.

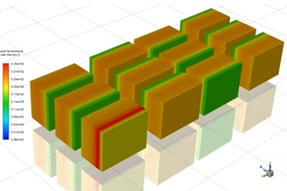

![]() ROMs enable engineers to model temperature distribution within a battery pack quickly, allowing data-driven decisions to optimize battery performance in terms of capacity, power output, and lifespan.

ROMs enable engineers to model temperature distribution within a battery pack quickly, allowing data-driven decisions to optimize battery performance in terms of capacity, power output, and lifespan.

Ansys Fluent is used for high-resolution Computational Fluid Dynamics (CFD) simulations to analyze the temperature distribution within a battery pack and identify areas for improvement. In tandem with Fluent, Ansys Twin Builder aids in constructing a battery Equivalent Circuit Model (ECM). The ECM predicts battery range, peak power, and drive-cycle performance, all crucial parameters in determining the overall performance of the battery and, by extension, the electric vehicle. By utilizing ROMs in battery thermal management, engineers can rapidly and precisely model temperature distribution within a battery pack. This rapid simulation of temperature and heat generation conditions allows battery designers to make data-driven decisions and adjustments that optimize battery performance. The ETC analysis, which includes the application of ROMs, allows for a thorough understanding of the thermal conditions in a battery.

2. Enhance Overall Safety

![]() Ansys Fluent and Twin Builder, in tandem, allow the creation of a detailed ETC analysis model that can predict potentially unsafe conditions, aiding in enhancing the overall safety of the battery system.

Ansys Fluent and Twin Builder, in tandem, allow the creation of a detailed ETC analysis model that can predict potentially unsafe conditions, aiding in enhancing the overall safety of the battery system.

![]() ROMs accurately simulate thermal conditions, helping identify and predict potential risks like thermal runaway. This ensures safe battery operation by preventing hazardous situations such as fires or explosions.

ROMs accurately simulate thermal conditions, helping identify and predict potential risks like thermal runaway. This ensures safe battery operation by preventing hazardous situations such as fires or explosions.

Safety is a paramount concern in electric vehicle design, especially considering the potential risks associated with battery failures. The Ansys software suite contributes to enhancing battery safety by enabling detailed ETC analysis. By coupling Ansys Fluent and Twin Builder, engineers can develop models that accurately predict potential safety risks under various operating conditions. This enables them to design systems that can prevent or mitigate these risks, thus enhancing the safety of the overall battery system. As ROMs provide accurate and fast simulations of thermal conditions within the battery system, they play a crucial role in ensuring safety. The swift identification and prediction of thermal risks prevent hazardous situations like thermal runaway, which could lead to fires or explosions. Consequently, effective use of ROMs in the thermal management system significantly contributes to safe battery operation.

3. Improve System Efficiency

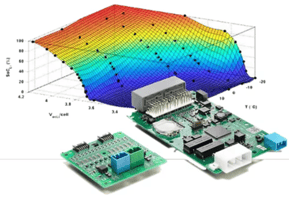

![]() The battery ECM generated by Ansys Twin Builder can encompass state of charge, temperature, discharge/charge, and rate dependency, assisting in the improvement of overall system efficiency.

The battery ECM generated by Ansys Twin Builder can encompass state of charge, temperature, discharge/charge, and rate dependency, assisting in the improvement of overall system efficiency.

![]() Swift and accurate simulation of thermal conditions using ROMs enhances energy conversion efficiency and reduces energy losses. Keeping the battery within its optimal operating temperature range improves overall system efficiency.

Swift and accurate simulation of thermal conditions using ROMs enhances energy conversion efficiency and reduces energy losses. Keeping the battery within its optimal operating temperature range improves overall system efficiency.

The battery ECM generated by Ansys Twin Builder, which can account for factors like state of charge, temperature, discharge/charge, and rate dependency, is instrumental in improving the system's efficiency. By simulating and understanding these parameters, engineers can make data-driven decisions to improve battery operation, ultimately enhancing the efficiency of the overall system. The rapid simulations enabled by ROMs alongside Ansys' powerful simulation tools allow engineers to assess battery response under different operating conditions and to a high level of certainty. With a clear direction to take with enhancing overall system efficiency early in the design process, the development timeline and budget are both greatly reduced.

4. Extend Battery Life

![]() Ansys Fluent generates models to simulate battery temperature, preventing harmful conditions and extending battery lifespan.

Ansys Fluent generates models to simulate battery temperature, preventing harmful conditions and extending battery lifespan.

![]() ROMs allow effective management of temperature variations, keeping the battery within its optimal temperature range. This significantly reduces battery degradation, extending its lifespan.

ROMs allow effective management of temperature variations, keeping the battery within its optimal temperature range. This significantly reduces battery degradation, extending its lifespan.

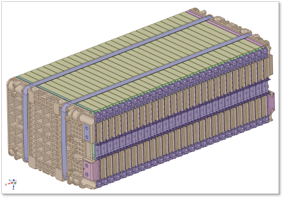

Another equally critical factor in EV design is extending the lifespan of batteries. Improper temperature management can significantly degrade battery life, making it a crucial factor to consider in design and operation. Ansys Fluent is used to generate high-fidelity CFD models of battery modules. This data is then used to create reduced-order models (ROMs) that simulate temperature given any transient heat source. Through rapid and accurate prediction of thermal conditions using ROMs, battery designers can effectively manage temperature variations within the battery system. This control over temperature fluctuations ensures the battery operates within its optimal temperature range, significantly reducing battery degradation and thereby extending its lifespan.

5. Maximize Vehicle Range

![]() Ansys Twin Builder's predictive models aid in optimizing the range of electric vehicles by considering battery parameters such as range, peak power, and drive-cycle performance.

Ansys Twin Builder's predictive models aid in optimizing the range of electric vehicles by considering battery parameters such as range, peak power, and drive-cycle performance.

![]() By simulating battery thermal conditions, ROMs help optimize the range of electric vehicles. Managing thermal conditions minimizes the impact of temperature variations on battery capacity and internal resistance, resulting in an optimized vehicle range.

By simulating battery thermal conditions, ROMs help optimize the range of electric vehicles. Managing thermal conditions minimizes the impact of temperature variations on battery capacity and internal resistance, resulting in an optimized vehicle range.

The range of an electric vehicle refers to the distance it can travel on a single charge, which is a key performance parameter for users. Range optimization involves adjusting various factors to ensure the vehicle can travel as far as possible on a single charge. Ansys Twin Builder's ECM construction wizard supports both 4P (one resistor-capacitor) and 6P (two RCs) types of ECM models. These models can predict crucial battery parameters such as battery range, peak power, and drive-cycle performance. By leveraging these predictive models, engineers can optimize the vehicle's range, making the vehicle more appealing to potential users. The use of ROMs in simulating battery thermal conditions aids in optimizing the range of electric vehicles. By efficiently managing the thermal conditions of the battery, designers can minimize the impact of temperature variations on battery capacity and internal resistance. This results in optimized vehicle range, an important factor for electric vehicles' overall performance and consumer acceptance.

Case Studies

Electronic Cooling Solutions

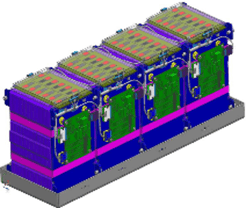

Electronic Cooling Solutions, a provider of thermal management expertise for the electronics industry, employed Ansys simulation software to optimize the design of a lithium-ion (Li-ion) battery pack thermal system. Li-ion batteries, a significant and expensive part of EVs, have a narrow optimal temperature range. An effective thermal management system can increase battery lifespan by maintaining cell and battery pack temperatures within a specific range, and prevent catastrophic battery failure.

Electronic Cooling Solutions, a provider of thermal management expertise for the electronics industry, employed Ansys simulation software to optimize the design of a lithium-ion (Li-ion) battery pack thermal system. Li-ion batteries, a significant and expensive part of EVs, have a narrow optimal temperature range. An effective thermal management system can increase battery lifespan by maintaining cell and battery pack temperatures within a specific range, and prevent catastrophic battery failure.

The approach taken by Electronic Cooling Solutions incorporated the use of Ansys Fluent and Ansys Twin Builder to develop and validate a reliable and cost-efficient battery pack temperature monitoring system. The firm used these tools to predict performance decay, troubleshoot, and validate aggressive design scenarios such as fast driving, cold starts, and fast charging. It was used to develop an efficient and effective thermal management solution that meets the stringent demands of EVs. This resulted in a significant reduction in computation time, from weeks to hours, contributing to a faster time-to-market. Click here to read the full case study.

LiTHIUM BALANCE

LiTHIUM BALANCE, a Denmark-based startup, utilizes Ansys medini analyze to expedite the ISO 26262 certification process for its battery management system (BMS) solutions. This certification is needed by the company to provide its BMS products to international electric vehicle manufacturers, in an increasingly saturated market. The BMS, a complex control system overseeing charging, energy storage, and daily operation of automotive batteries, is critical for the functional safety of the entire vehicle. Therefore, the BMS solutions by LiTHIUM BALANCE must conform to the rigorous demands of ISO 26262 to penetrate the global automotive market.

LiTHIUM BALANCE, a Denmark-based startup, utilizes Ansys medini analyze to expedite the ISO 26262 certification process for its battery management system (BMS) solutions. This certification is needed by the company to provide its BMS products to international electric vehicle manufacturers, in an increasingly saturated market. The BMS, a complex control system overseeing charging, energy storage, and daily operation of automotive batteries, is critical for the functional safety of the entire vehicle. Therefore, the BMS solutions by LiTHIUM BALANCE must conform to the rigorous demands of ISO 26262 to penetrate the global automotive market.

Ansys medini analyze plays a crucial role in accelerating and streamlining the ISO certification process. As a user-friendly, model-based tool, medini analyze aids LiTHIUM BALANCE in identifying potential battery failure rates and mechanisms across various operating scenarios. Furthermore, it documents how the BMS will respond to each of these situations. The deep analytic capabilities offered by medini analyze ensure there will be an adequate response to every conceivable battery failure, demonstrating that LiTHIUM BALANCE's BMS solutions are functionally safe under almost every operating condition.

This tool has not only helped LiTHIUM BALANCE earn its ISO certification but has also positioned it to develop BMS solutions for new markets and applications, including drones, robots, and industrial equipment. Click here to read the full case study.

The Future of EV Battery Design and Optimization

State-of-the-art simulation tools like Ansys Fluent and Twin Builder, augmented with Reduced Order Models (ROMs), enable comprehensive Electro-Thermal Coupled (ETC) analyses that are pivotal in the refinement of key battery design components. This includes the optimization of performance, bolstering safety protocols, improving efficiency, extending battery life, and maximizing range.

Ansys software facilitates the creation of precise battery equivalent circuit models (ECMs), accurately predicting essential parameters such as battery range, peak power, and drive-cycle performance. This predictive capability is paramount in pushing the envelope of EV range - a factor greatly impacting potential users and overall consumer acceptance of electric vehicles. As we stand on the precipice of a predominantly electric automotive future, these leaps in battery design optimization signify significant progress in surmounting the current challenges in the EV industry. As this industry continues to evolve and innovate, the methodologies and tools advanced by Ansys will remain instrumental in the production of more secure, efficient, and reliable electric vehicles.

Ansys software facilitates the creation of precise battery equivalent circuit models (ECMs), accurately predicting essential parameters such as battery range, peak power, and drive-cycle performance. This predictive capability is paramount in pushing the envelope of EV range - a factor greatly impacting potential users and overall consumer acceptance of electric vehicles. As we stand on the precipice of a predominantly electric automotive future, these leaps in battery design optimization signify significant progress in surmounting the current challenges in the EV industry. As this industry continues to evolve and innovate, the methodologies and tools advanced by Ansys will remain instrumental in the production of more secure, efficient, and reliable electric vehicles.

To learn more about Ansys solutions for EV battery optimization, join our upcoming webinar "Creating Thermal Models of Automotive Batteries" on July 26th, 2023.

Watch our demonstration of Ansys Fluent, using a Reduced Order Model (ROM) approach, to predict the thermal behavior of a battery under common operating conditions. Click here to learn more about the event and how to join it.

Jul 13, 2023 7:32:40 AM