SUMMARY:

In many real-world engineering scenarios, components are subjected to a combination of static loads and dynamic oscillations. For example, a bracket might be preloaded due to assembly forces (static stress), while also experiencing vibrations from an engine or rotating equipment (harmonic stress). Evaluating the fatigue life of such components requires considering both effects simultaneously — this is where the synergy between Ansys and nCode DesignLife becomes powerful.

In this blog post, I’ll walk you through how to combine two types of stress analyses — static and harmonic — using Ansys and nCode, to solve fatigue problems where the harmonic stress oscillates around a non-zero mean stress. Using a Workbench fully integrated workflow with nCode DesignLife, a simple example is solved to explain each step.

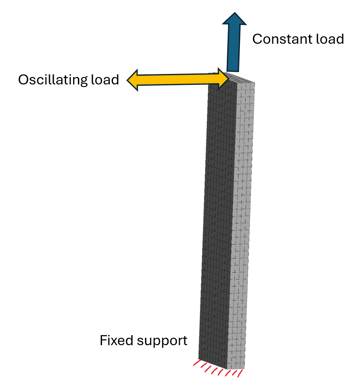

The model

Our model is very simple: just a cantilever beam subjected to a bending load that oscillates sinusoidally between equal positive and negative values, resulting in a zero mean load. This is precisely the definition of a harmonic load. In addition, there is a constant axial force that does not vary with time and is solved using a static analysis.

While this loading scenario could be solved using only the Fatigue tool in Mechanical with two static analyses, in general, a harmonic analysis cannot always be replaced by static ones. The purpose here is to demonstrate how to account for both load types in a fatigue assessment.

Step 1: Perform Static Analysis in Ansys Mechanical

Start by setting up a static structural analysis in Ansys Mechanical. This simulation will capture the constant (mean) stress state due to preload, gravity, thermal expansion, or any other sustained force. Then, define the boundary conditions and loads that contribute to the static stress and solve the model. This static result will serve as the mean stress baseline for your fatigue analysis.

In the example, a fixed support and an axial load of 10 MPa do the work. Mostly uniform stress of 10MPa is found as expected.

Step 2: Perform Harmonic Analysis

Next, set up a harmonic response analysis for the same model and apply the dynamic loading (e.g., sinusoidal forces, base excitation). Ensure that the frequency range and mode resolution are sufficient to capture the stress fluctuation pattern. For Harmonic fatigue, just one frequency of interest could be enough. This analysis yields oscillatory stress results, typically varying around zero mean.

In our example, a harmonic bending force is created to create bending stresses. Note how the normal stress varies from -25.9 MPa to 25.9 MPa in the bottom edge when the sweep phase change from 0 to 3.14 rad (a half cycle).

Step 3: Prepare for Fatigue Analysis in nCode DesignLife

Now, is possible to import both sets of stress results into nCode DesignLife. nCode allows you to combine multiple stress inputs using the nCode SN VibrationSweptSine (DesignLife) module in Ansys Workbench.

Is necessary to use the same mesh for both structural analyses to guarantee the compatibility in nCode. Connecting both structural analyses in Material, Geometry and Model levels in Workbench is the best and easy way to accomplish this. Note the nCode module also requires the same connections, and the results from both Structural and Harmonic analyses to the solution block in nCode.

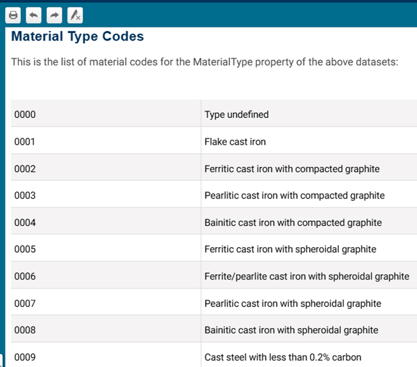

In Engineering data, include the SN curve as a function of the R-Ratio and include the nCode Material type property.

The Material type full list is available in the nCode help.

Step 4: Perform Fatigue Analysis

By opening the nCode SN VibrationSweptSine (DesignLife) block, we can see the typical Glyph nCode environment. Please do not be overwhelmed by these pre defined pipes and blocks, they are carefully set to solve your analysis.

The SweepSine_Analysis Glyph is the core SN fatigue solver in this analysis. Its key feature is the ability to combine time-domain results from the static analysis with frequency-domain results from the harmonic analysis via two input pads. By default, the frequency-domain results are connected to the FRF Input pad, and the static results to the Offset Loadcase Input pad. If you add the Glyph manually, ensure the connections are made in this way.

Some additional configurations are needed to accomplish our example exercise objectives.

- SweepSine_Analysis Glyph setup. The properties window is used to set up the analysis. Common properties, such as CombinationMethod and MeanStressCorrection, are set to default values but can be modified to suit the analysis objectives. For the single-frequency harmonic analysis intended here, the LoadingMethod is set to SineDwell to avoid sweeping over frequency. The SineDwellFrequency specifies the frequency at which the harmonic vibration is applied and from which the stress state is extracted from the results file. The SineDwellDurationSeconds property defines the duration of the load scenario.

- Load Mapping. In the SweepSine_Analysis glyph we can access the 'Edit Load Mapping option' by right click.

In the FRF tab, be sure the frequency domain results file is selected in the Case Assignments column.

The Static tab allows to select the corresponding results file. Note the Scale factor, this allows to proportionally modify the input stress.

- Vibration Generator. This Glyph is connected to the SweepSine_Analysis using the HistogramPipe input pad to create a frequency dependent scale factor to modify the Harmonic results. For a one frequency analysis, a constant value is fine. Be sure this is set properly in value and frequency range. In this example we are interested in solving for 20 Hz.

- Results. Is possible to review tabular or contour plots using the DataValuesDisplay and Fatigue_Results_Display respectively.

Inspecting the contour results, in this example we can see how the mean stress calculated fits the expected value of 10 MPa applied in the Static analysis.

The Stress Amplitude corresponds with the Harmonic result at 20 Hz. This is how the loads addition was intended to be considered for fatigue evaluation:

Life results shows minimum value of 62270 cycles at 20 Hz = 3113 sec.

Final Thoughts

Using Ansys and nCode DesignLife together enables engineers to simulate complex loading environments with confidence. By superimposing harmonic and static stresses, you can better understand the true fatigue behavior of your components — leading to safer, longer-lasting designs.

If you’re routinely dealing with combined loading scenarios, integrating this workflow into your analysis process can significantly improve fatigue prediction accuracy.

Downloadable Resource

Related content

For more details, visit the Youtube video

Ozen Engineering Expertise

Ozen Engineering Inc. leverages it's extensive consulting expertise in CFD, FEA, thermal, optics, photonics, and electromagnetic simulations to achieve exceptional results across various engineering projects, addressing complex challenges like multiphase flows, erosion modeling, and channel flows using Ansys software.

We provide expert consulting, mentoring, and training to optimize hydraulic and water control systems. Our team leverages advanced simulation tools like Ansys Fluent to deliver precise, reliable solutions for piezoelectric actuator design and analysis. For details, visit https://ozeninc.com.

Tags:

Static Structural, Harmonic Response, Structural Analysis, ANSYS Mechanical, Fatigue Analysis, nCode, 2025 R1Aug 18, 2025 10:01:51 AM