Glass Bottle Packaging Drop Analysis Using Ansys LS-DYNA

Glass Bottle Packaging Drop Analysis

- Two glass bottles, one with carton packaging, are used to demonstrate the effect of packaging.

- Johnson–Holmquist damage model is used for Glass (MAT_JOHNSON_HOLMQUIST_CERAMICS)

- The isotropic elastic material model is used for carton box packaging.

- Bottles will be dropped from a height of 300 mm.

Figure 1: Geometries

- Below are some animations and results of the drop analysis of bottles:

Animation 1: Drop Analysis Result

Animation 2: Drop Analysis Result (Packaging is hidden)

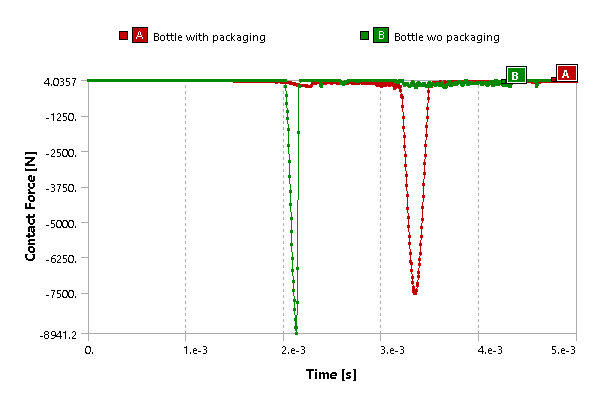

Chart 1: Contact forces of bottles

The results clearly show that when dropped from a height of 30 cm, one of the two bottles, which had no packaging, cracked, while the other bottle remained intact. Notably, the bottle without packaging experienced a sudden and sharp increase in force at the moment of impact, whereas the packaged bottle experienced a gradual and smooth increase in force. Furthermore, the maximum force exerted on the packaged bottle was 7500 N, whereas the force on the unpackaged bottle reached a maximum of 8900 N, leading to its breakage. These findings demonstrate that packaging plays a crucial role in absorbing energy, acting as a barrier that protects the bottle. It effectively dampens the falling energy and prolongs the duration of the fall. In conclusion, The results emphasize the crucial role of packaging in absorbing energy, acting as a protective barrier.

For a more comprehensive understanding of the modelling process, we recommend referring to our demonstration video, which can provide additional valuable insights about modelling it in Ansys Ls-Dyna.

Tags:

Mechanical, Ansys, packaging, Ls-Dyna, lsdyna, package, drop analysis, glass material, glass bottle, johnson HolmquistJul 24, 2023 1:50:36 PM