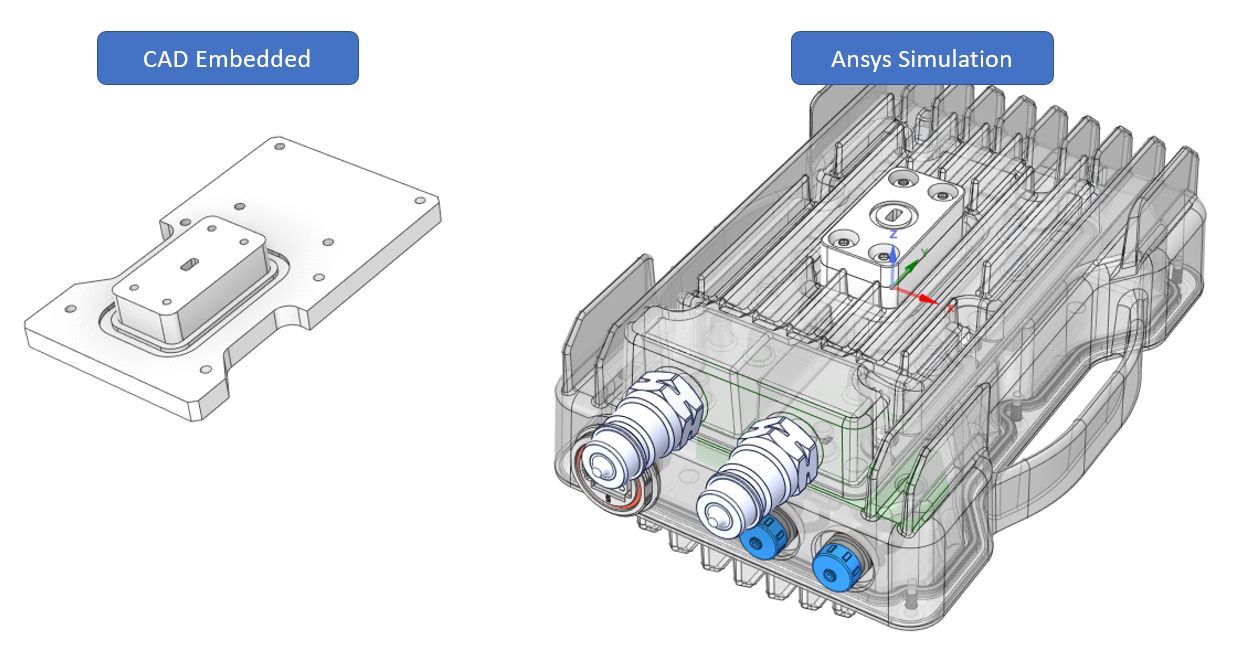

CAD embedded simulation tools are pretty great!

Solidworks, Creo, NX even Fusion 360 all have some levels for FEA and maybe CFD embedded. They are pretty great because...

- Easy to use since you are already familiar with the GUI

- Easy to use because you don't have to transfer geometry to another tool

- Easy to use because only a few features and functions are available

- Cheap!

I'm going to give a few examples about when engineers feel the need to upgrade to more powerful solutions like Ansys.

Need for speed

This seem counterintuitive on the surface but professional simulation tools like Ansys can make simulation much faster. Just like a chain saw is much faster than a handsaw when you need to clean up a tree that fell over and crushed your picnic table.

Time to upgrade from that hand saw to a chain saw!

So what's the equivalent of a fallen tree in the simulation world?

Assemblies

Often part level simulations can be done quickly in CAD embedded simulation tools. However, interesting thing often occurs when parts interact with each other. System level simulations can often be tackled much more efficiently in tools like Ansys mechanical.

Key features are

- Automatic contact detection

- Lots of connection options - contacts, joints, beams, springs, mesh connections and welds.

- Fracture, debonding, delamination

- Automations for setup and post process geared towards large models

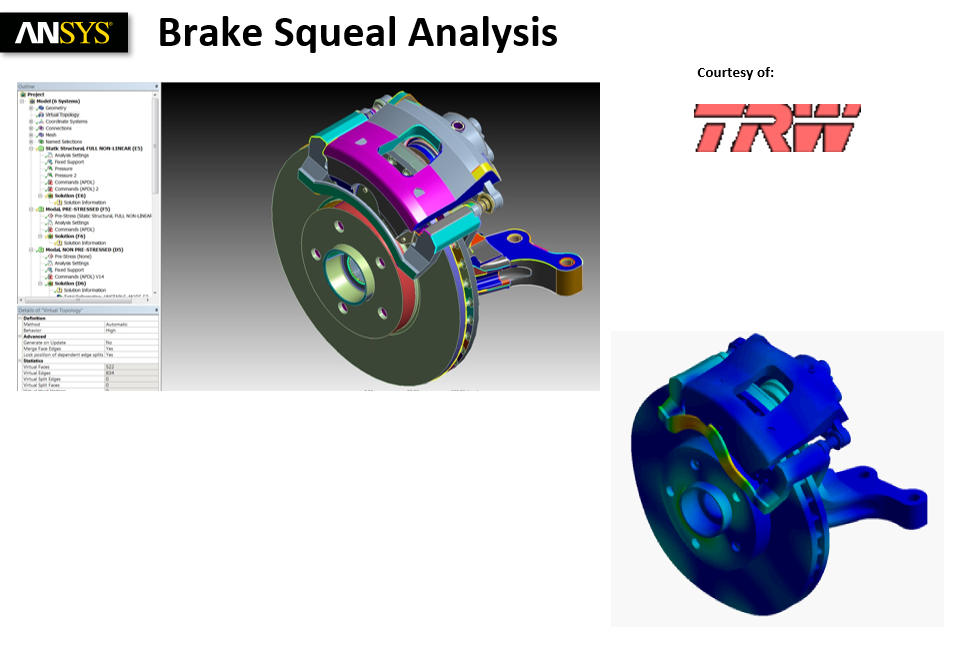

Sliding/Separating contacts

Different parts are often not welded together. In fact most parts are held together by fasteners or friction.

Here is a selection of YouTube video that demonstrate this modeling for press fits and bolts.

The magic is in the contact detection, stabilization and convergence algorithm. Nonlinear contacts can be pretty challenging, however Ansys as a lot of options available to help you achieve a converged solution. Even better, Ansys is highly automated such that even complex non-linear contact problem converges "out of the box" or with just a couple of simple adjustments.

Here's another example of sliding/separating contacts where we look at the interaction between 2 parts of a USB connector.

Vibrations, impacts and other dynamics

Do you ever worry about product failure due to vibration loads? Have your products failed during vibration testing? That's usually when we get called. Here are a couple of examples

- 3 of my prototypes broke last night during random vib testing and I need to get our prototype working asap

- The brackets sheared off during vib testing, we made it thicker and it broke again. Now we are a week behind schedule

- Our equipment is supposed to last 20 years, but we are seeing many in field failures after only 5 years. Why is it happening?

Vibration is the results of complex interplay between stiffness, mass and damping. The behavior can be unintuitive and the solutions to failures can be unintuitive as well. The entire assembly often need to be included to capture realistic results. This is why advanced simulations like Ansys is commonly used to address these problems.

Here is an introduction videos on random vib.

Typically we demonstrate small simple parts for vibration analysis because large models can require a lot of computational resources. However we have some pretty advanced techniques to break up large problems and make the simpler.

One easy to use method is the component mode synthesis / substructuring /super-element method. This methods allows different parts of an assembly to be characterized separately, then combine to evaluate the system level vibration behavior.

We will put up some good examples of vibration using sub structuring using both top-down and bottom up techniques soon.

Sometimes you need to deal with more non-linear dynamic events like this

Drop, impact, crash and penetration simulations are highly nonlinear dynamic simulations. These can get pretty tricky and we often see companies export advance simulation tools to ensure durability during these situations.

Advanced Materials

I love linear materials, easy to solve, never give you any problems. However sometimes the material you work with is non-linear, sometimes, you just can't get away with a linear assumption because the results are just too different. In these cases we often see customers upgrading there simulation environment to something more advanced like Ansys.

I will show a few examples of nonlinear materials here and some typical applications.

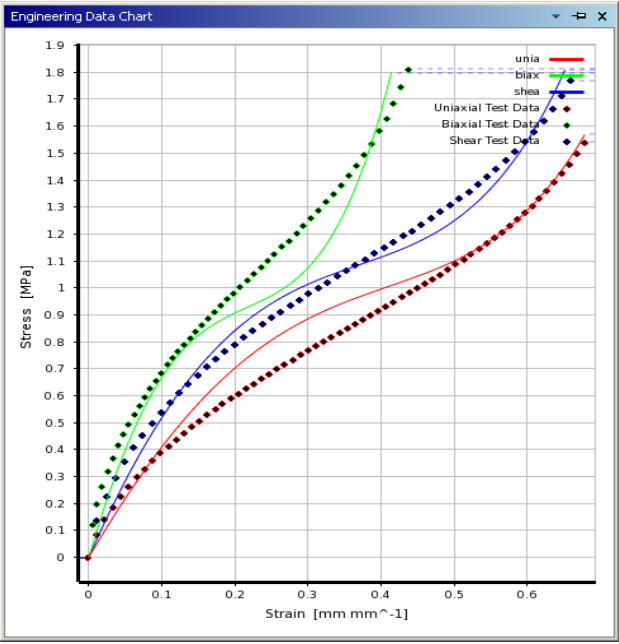

Rubbers

Here is a hyperelastic material model, typically used to represent elastomers/rubber/soft squishy things

Rubbers can get even more complex if it is anisotropic, or if it experience stretch softening like this Mullins effect below

Plastics

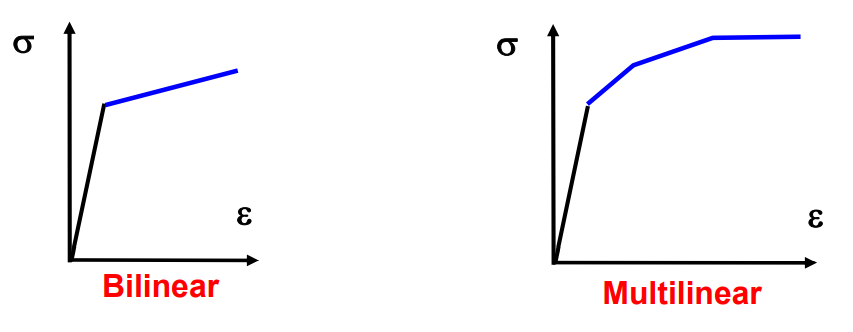

Not all polymers are soft and squishy though. We also model plastics which can often be modeled as simple bilinear or multi-linear materials

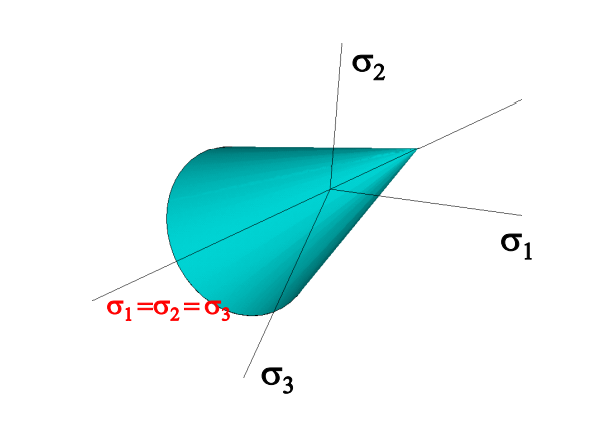

However plastic yielding can be pressure dependent. Then we need to use a material model like Drucker-Prager

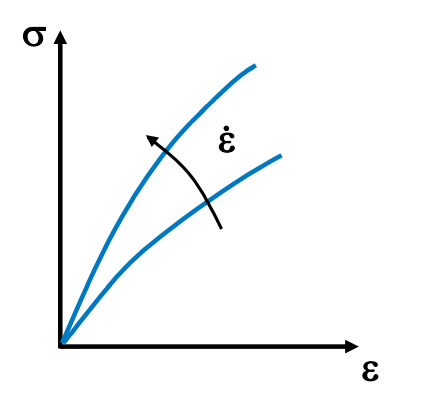

Some plastic may have rate dependent behavior used for damping. They we need viscoelasticity.

Metals

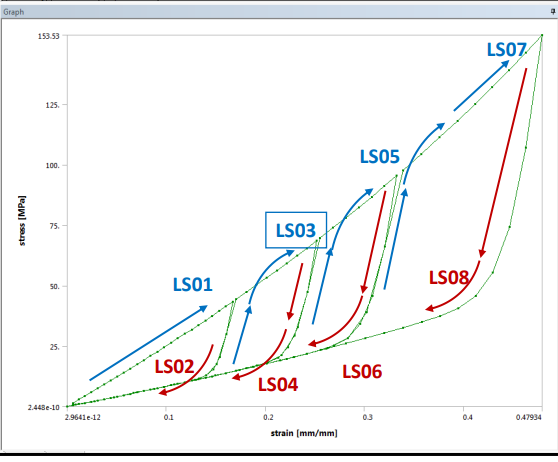

Metals can become plastic with enough load, which makes them non-linear

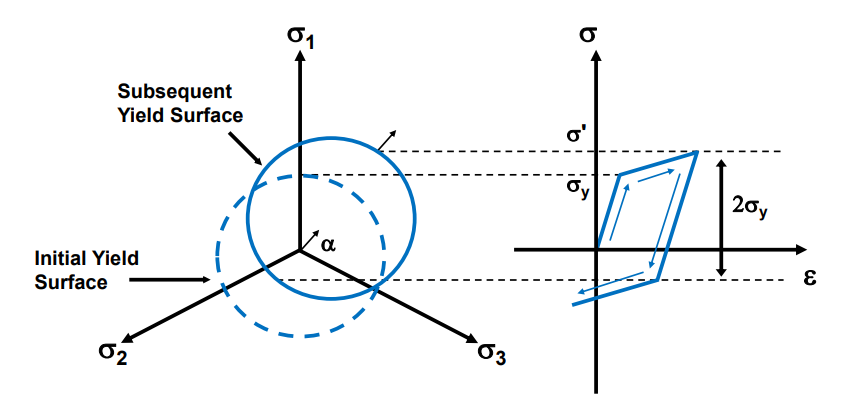

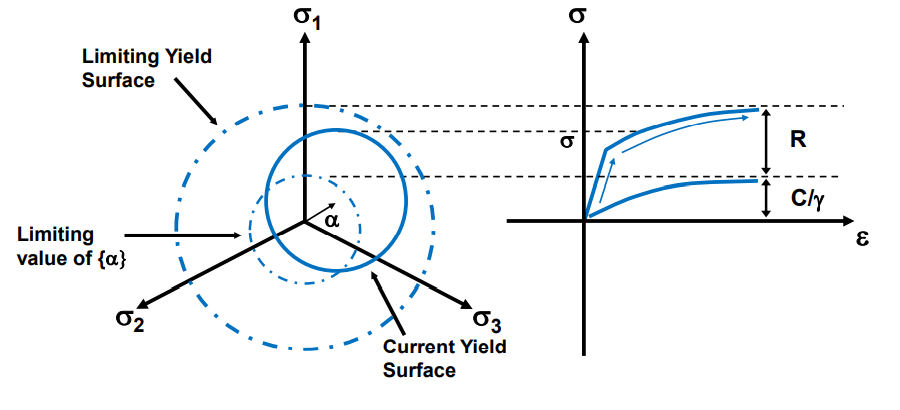

However metal plasticity can be even more nonlinear if you need to include ratchetting and shakedown behavior

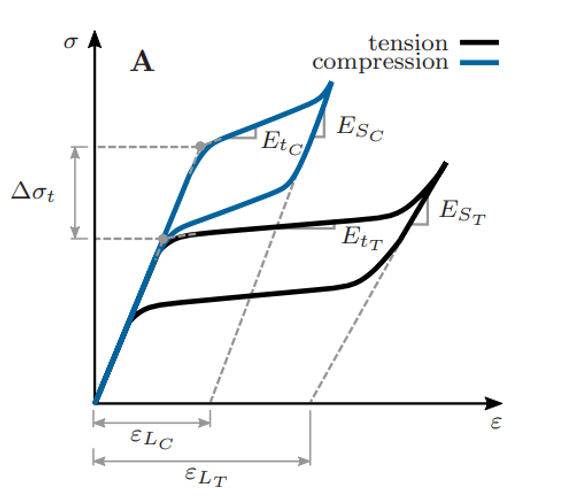

Then you have even more complex metals like shape memory alloys (SMA). These material have different load and unloading curves due to phase transition. Different stiffness in different phases, different compression vs tension behavior. It will even change shape when heated or cooled down! Imaging how complex your eye-glass frame and cardio vascular stents are to simulate!

We also have advanced models for cast iron, anisotropic plasticity and many other complex model for metals.

Materials can get complex, so if your current simulations is not able to capture how your material actually behaves then it could be time to think about Ansys.

Support and 100 little things

The above are hard, concrete reason on when you should think about upgrading your CAD embedded simulation tools to professional tools like Ansys. However the biggest advantage to switching to a tool like Ansys is the support available from the folks on my team. The majority of us have decades of experience in simulation. We will quickly tell you

- Can you solve your problem using simulation

- Is it hard or easy

- Best approach and how to find the right trade-offs between accuracy and speed.

- Those unknow-unknows that always trips people up the first time they try something.

I'll conclude with this piece of advice that I give out too many times.

Simulation is a process, you need to do every step right to get the right answer. Ansys has been solve structural simulation problems for 40 years and some on our team have been working on this for almost as long. We know our software has all of the 100's of little things you need to get an accurate answer and we make sure you are successful.

Thank you for reading through this.

I'd love to hear if you have any suggestions on other scenarios.

Tags:

Jul 19, 2022 4:56:20 PM