Hello,

In this blog I give an overview of how to use Ansys Motor-CAD model, simulate, analyze, and post process results to evaluate motor performance and help you select an optimized motor for your application and achieve cost effectiveness and efficiency with your motor design selection. I go over the various motor types available, physics modules to choose from, and multi-physics options to configure. Ansys Motor-CAD is an exclusive motor design tool that is capable of solving analytical motor models, and provide 2D FEA results. The models can be solved for single physics (electromagnetic, thermal, and mechanical) or can be coupled all together to solve a unified physics model of the motor. Also, the LAB module can be used to apply complex duty cycles and produce efficiency maps to evaluate the performance of the motor.

TYPICAL USES OF MOTOR-CAD

Motor-CAD is often used for the following tasks:

- Design Optimization - Motor-CAD can be used as an integral part of the design process. By optimizing the electromagnetic model in parallel with the thermal circuit and mechanical design a true optimum design is achieved. Often the thermal design aspects are left until the end of the design process, at which point it is too late to alter the design and a sub-standard motor is produced.

- Rapid Response to Customer Enquiries - Often a customer wishes to use an existing motor for a given application that has a specified load characteristic. Motor-CAD can be used to rapidly model the load specification using its duty-cycle analysis capabilities. The designer then has a clear understanding of whether the motor/drive combination is adequate for the task and the customer has a sense of security that the designer has fully investigated his enquiry - so helping to win orders.

- Rapid Quantification of Design Changes - Occasionally a change in material or manufacturing process may be proposed. Motor-CAD allows the designer to quickly quantify the effects of such changes on the motor’s performance.

- Program Validation - It is easy to compare Motor-CAD calculation of the machine performance with tests on existing motors. In carrying out such validation the user gains a deep understanding as to what are the main parameters that affect the machine’s performance and so can use this knowledge to improve the design.

- Parameter Estimation - Often it is very difficult, if not impossible, to directly measure certain key parameters that affect a motor’s performance, e.g., interface gaps, rotor losses. In many cases these parameters can be estimated by matching Motor-CAD output with data that can be readily measured, e.g., component temperatures, stator losses. For instance, the interface gap between stator-lamination and housing can be varied until a match is given with the measured values of T[stator] & T[housing].

- Sensitivity Analysis and Robust Design - It is very easy to vary input parameters and examine the effect on the machine performance, temperature distributions etc. Sensitivity analysis can be used on parameters such as dimensional tolerances, material properties, impregnation goodness, interface gaps, etc. and plot graph of the variation in machine performance. This can be used to gain an insight into which are the critical design variables in the machine. It can also be extended to form part of a system model in Robust Design techniques such as 6-Sigma. The whole calculation process together with the variation in the relevant parameters can be automated using ActiveX technology or by using the inbuilt Sensitivity Analysis tool.

MOTOR TYPES

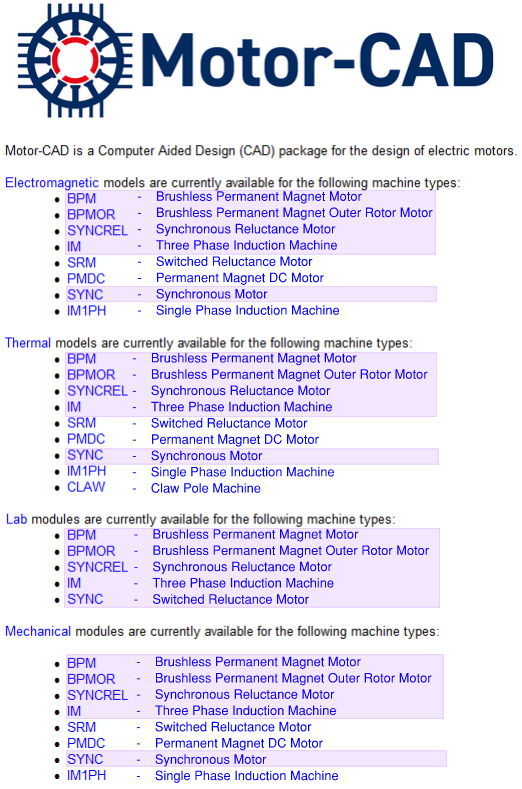

Ansys Motor-CAD has nine industry based standard motor types to choose from and five of these types (highlighted in purple below) are available for design of experiments to develop torque vs speed curves and produce efficiency maps to evaluate motor performance for various motor drive cycles.

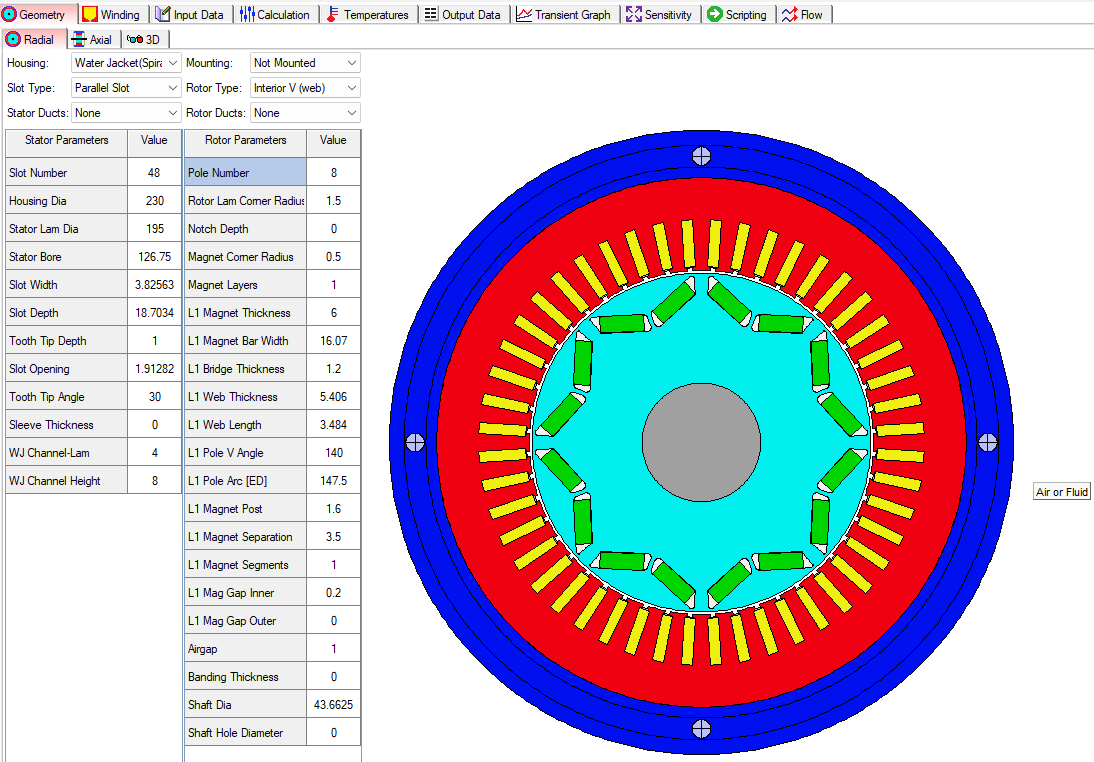

GEOMETRY TEMPLATE

Ansys Motor-CAD uses templates to create the motor geometry. Below is template for a Brushless Permanent Magnet motor, for example. Each motor design will have specific geometry parameters for the particular motor type selected. Also, Motor-CAD has tabs for radial, axial, and 3D views. The different physics modules will show relevant geometry for the physics module selected. For example, the Thermal physics module shows the parameters and geometry for the motor jacket or encloser if one is selected.

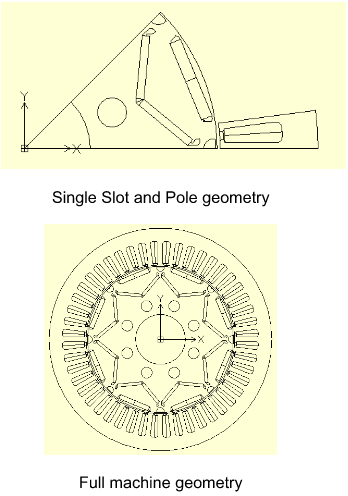

Alternatively, the user may import DXF files for the motor geometry as long as the geometry is close to the standard geometry. It is recommended to use a single slot/pole DXF geometry if possible as this allows Motor-CAD to use the machine symmetry to reduce computation time. If a full machine custom DXF geometry is used, then Motor-CAD will always solve the full machine and will therefore take longer to solve.

In order to use an imported DXF geometry, it must obey the following requirements:

1. The rotation axis must be centered on the origin (0, 0).

2. The imported stator and rotor components must be oriented so that the lower edges of

each sector are aligned on the x axis.

3. The airgap boundaries must be formed by concentric circles or arcs forming a smooth

continuous inner and outer surface. This requires that all slot openings be closed and

any eccentricity on either surface are buffered from the airgap mesh region by arcs

centered on the origin.

4. Each slot region needs to be divided into two regions in order that the current density

can be assigned correctly.

5. The positions and alignment of the DXF geometry must match those of the single slot

and pole or full machine geometries below.

6. The DXF file must be saved in R12 ASCII drawing format.

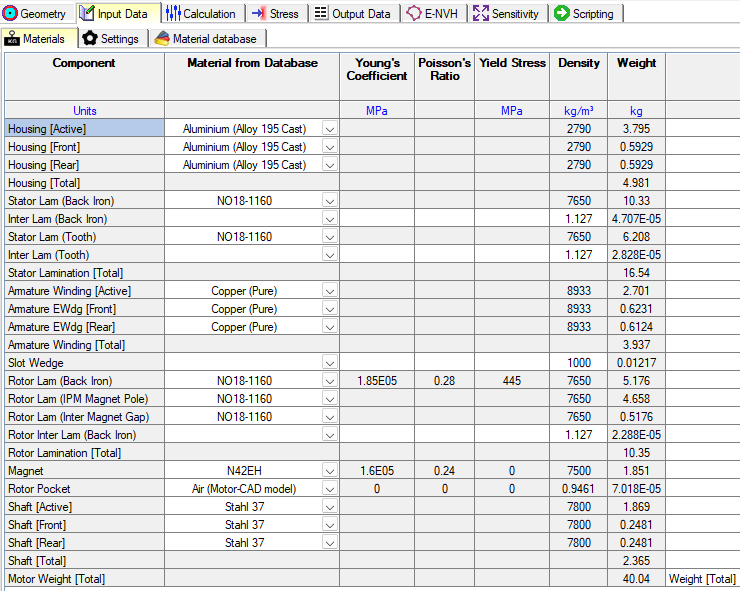

ELECTROMAGNETICS - E-Mag

The E-Mag physics module has many tabs to cover all of the settings for the geometry creation, material selection, electromagnetics settings, conditions, solver types, solution models, coupling settings, etc.

Electromagnetic Model

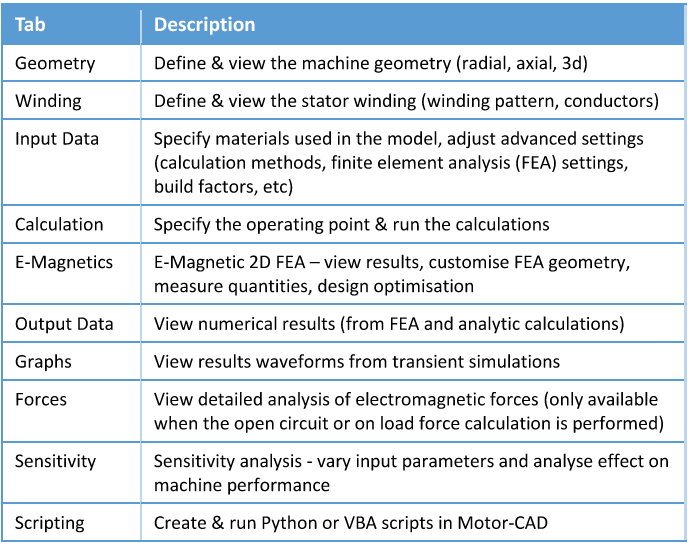

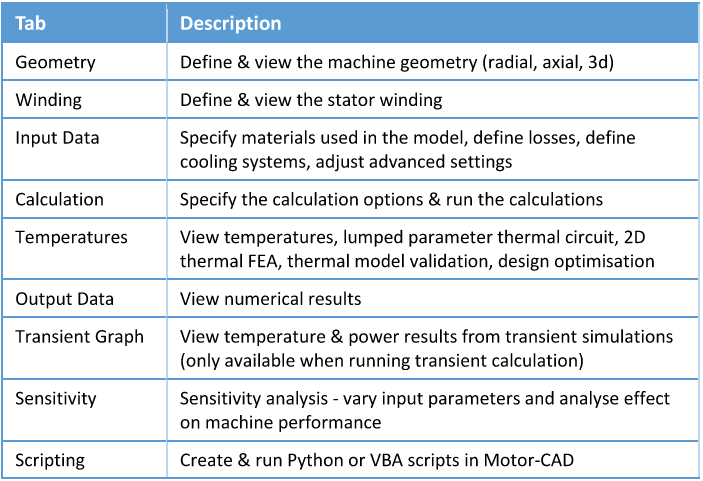

The following main tabs are available in the E-Magnetic context for sine-wave driven BPM

machines. Generally in Motor-CAD we work through the tabs from left to right in order to set

up the model, run the calculations and analyze the results.

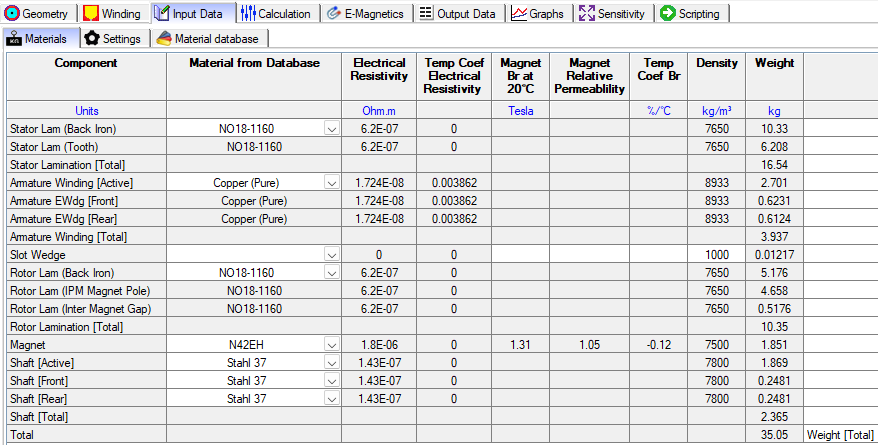

Electromagnetic Model - Material

The materials tab has relevant physics parameters for the Electromagnetics module.

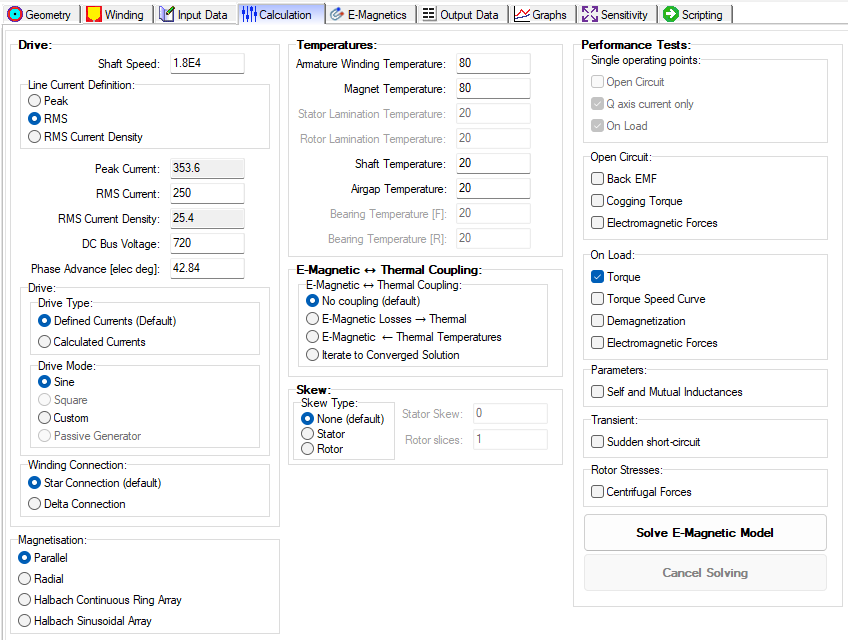

Electromagnetic Model - Calculation

The Calculation tab has relevant settings and options for the Electromagnetics module.

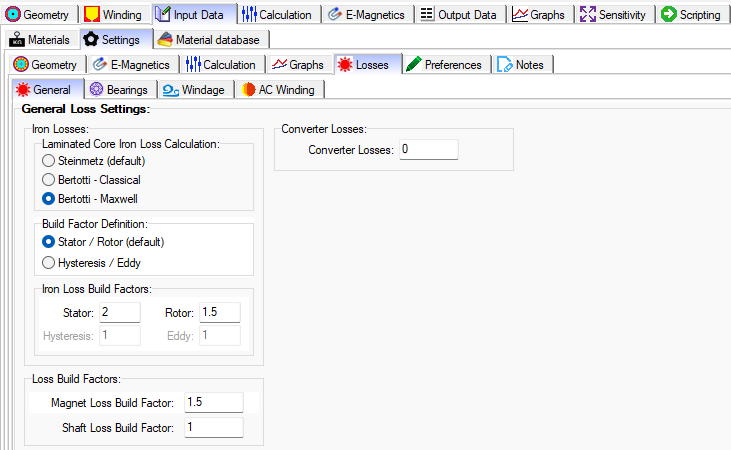

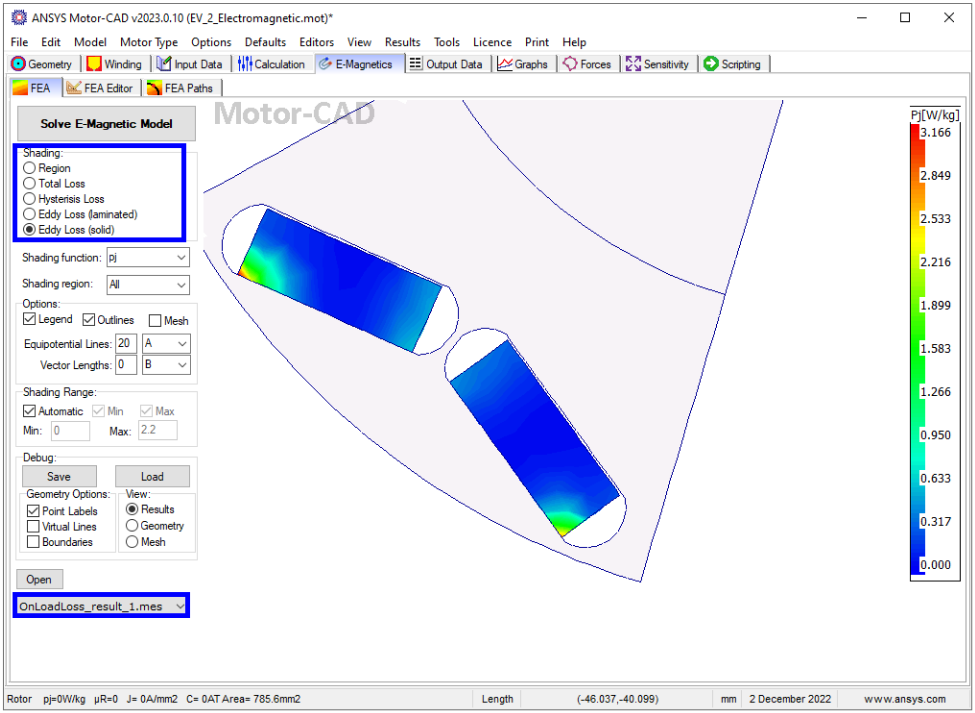

Electromagnetic Model - General Loss Settings

Apply the Steinmetz model for ferrite material, and the Bertotti model for Electrical Steel material. Also, there are various models for losses of the bearings, windage, and AC winding.

Electromagnetic Model - Analysis

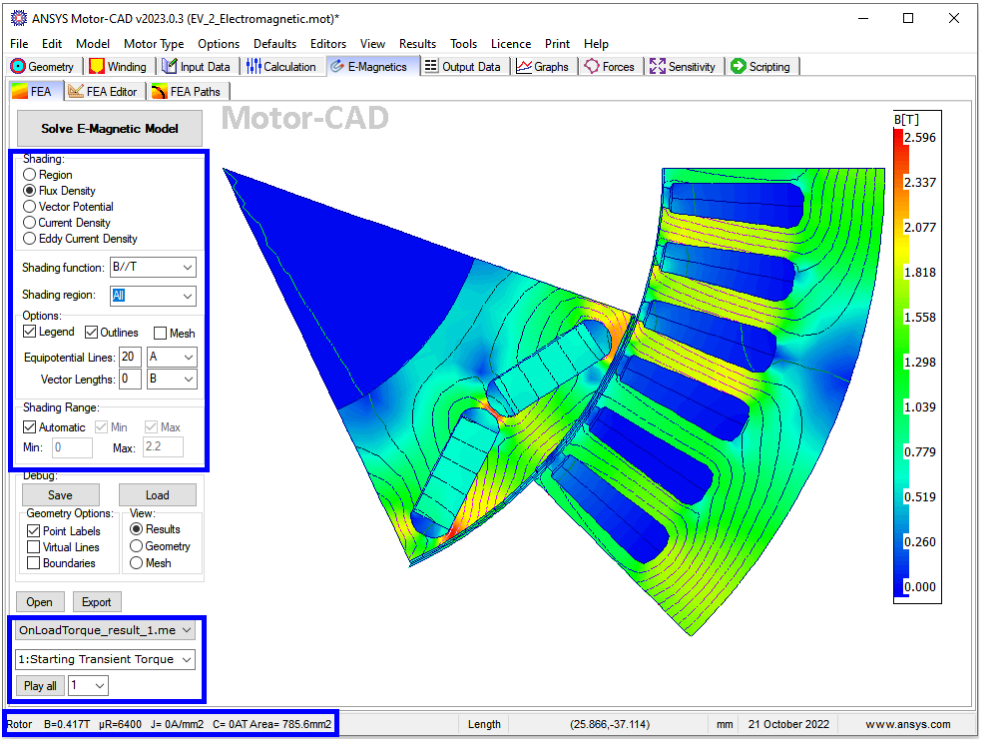

The E-Magnetic module in Motor-CAD allows 2D FEA electromagnetic analysis and loss

calculation to obtain the working conditions and performance of the machine. It also has an

automatic link to the thermal model in Motor-CAD for subsequent thermal analysis.

'

'

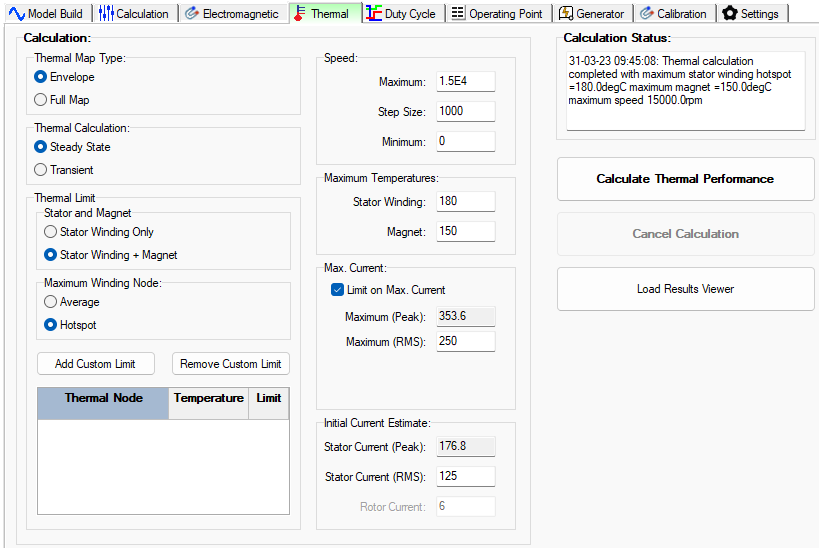

HEAT TRANSFER - THERMAL

The Thermal physics module has many tabs to cover all of the settings for the geometry creation, material selection, thermal settings, conditions, solver types, solution models, coupling settings, etc.

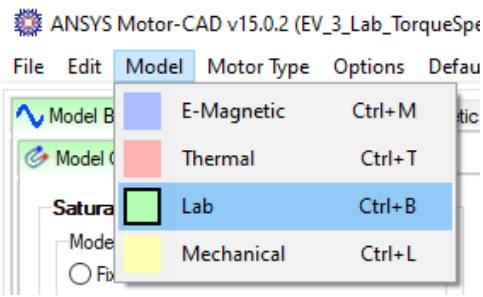

Thermal Model

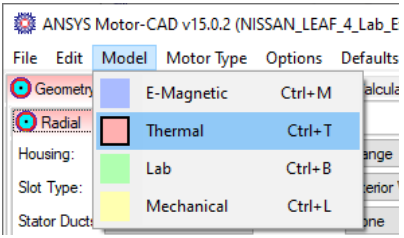

The thermal model in Motor-CAD solves lumped parameter thermal networks in order to obtain

the working temperatures of the machine. FEA thermal simulations can also be used in order

to validate the lumped parameter model. Switch to the thermal context with Model -> Thermal or Ctrl+T (tip: a red background on the active tab indicates thermal context). Save the file as EV_5_Thermal.mot.

The following main tabs are available in the thermal context:

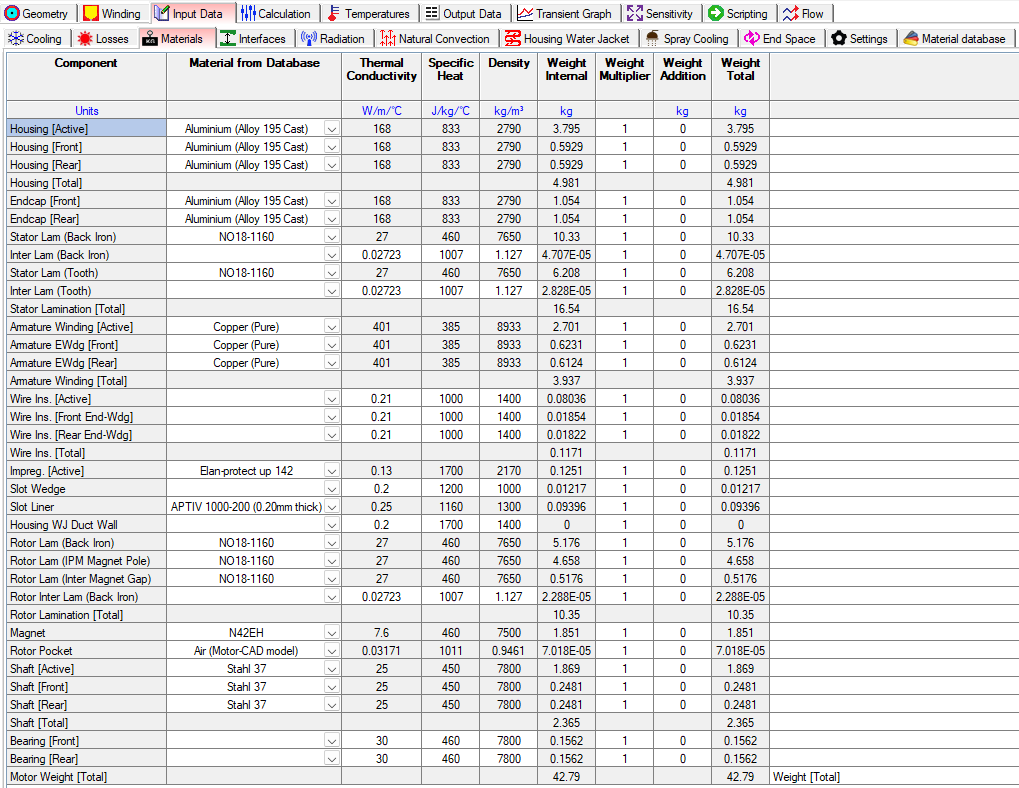

Thermal Model - Material

The materials tab has relevant physics parameters for the Thermal module.

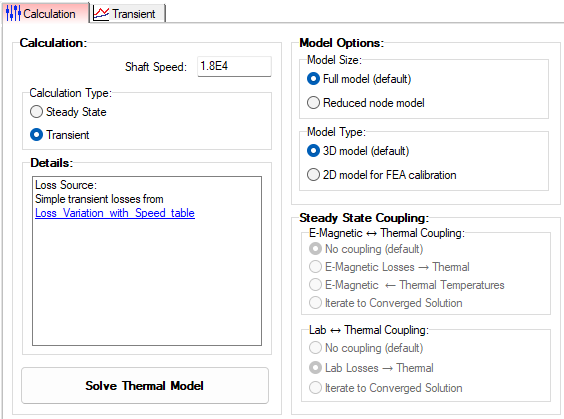

Thermal Model - Material

The Calculation tab has relevant settings and options for the Thermal module.

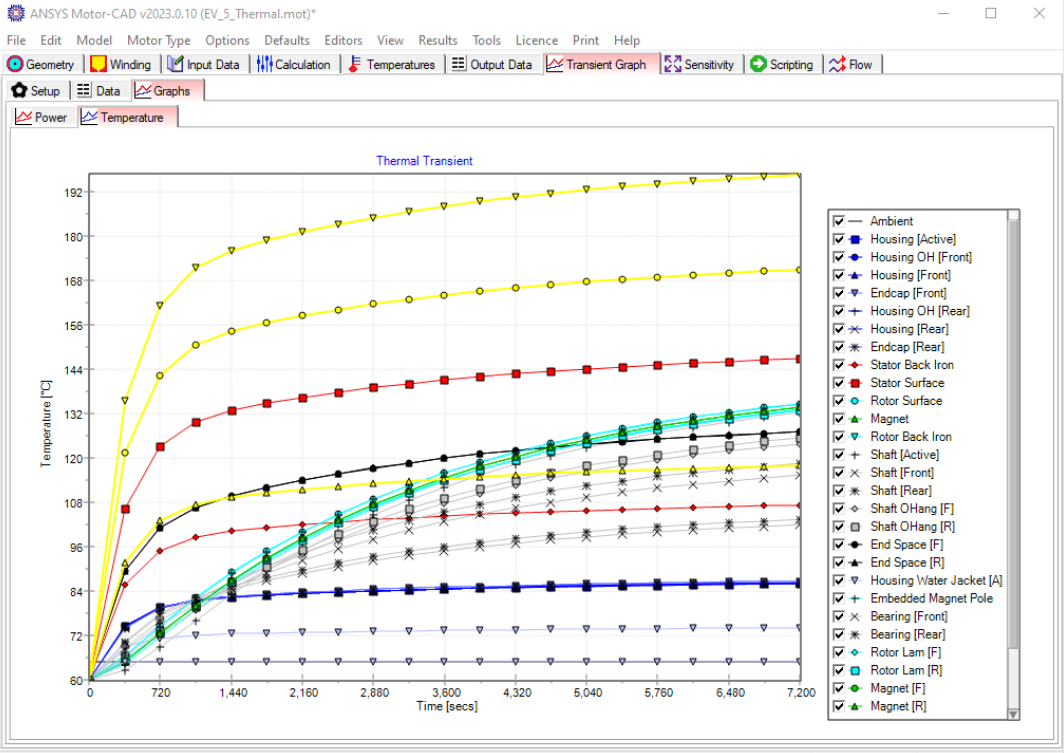

Thermal Analysis

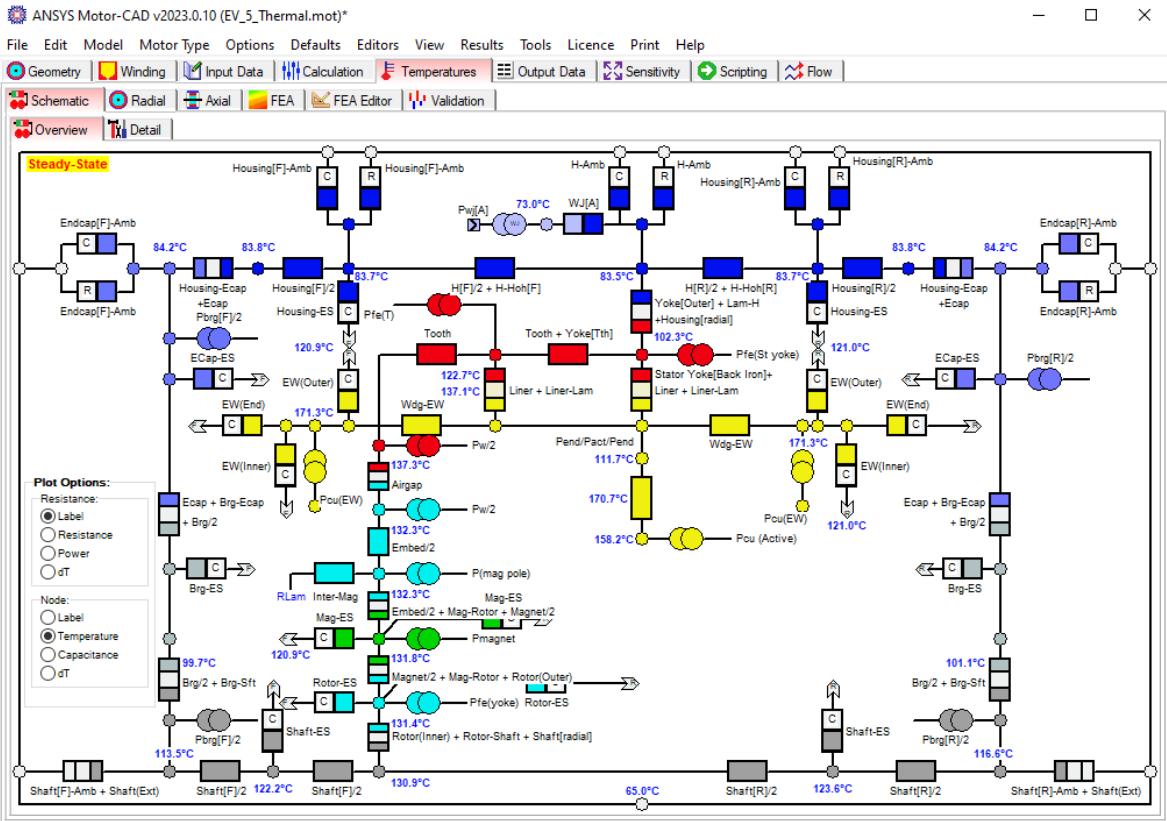

Based on the input geometry, losses and model settings Motor-CAD creates a 3D lumped

parameter circuit model to

•Characterize the thermal behavior of the machine for Steady-state or transient calculations.

•Simple or complex Duty Cycles.

•Evaluate continuous thermal performance with Lab coupled with Thermal.

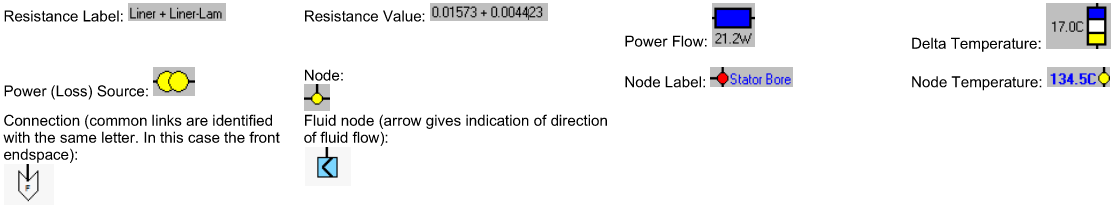

Each component is represented with a thermal resistance and capacitance. Losses are represented as power sources, and power is dissipated to the ambient node by the cooling systems. By solving this equivalent thermal circuit, Motor-CAD can accurately estimate the temperatures in each part of the machine.

Legend:

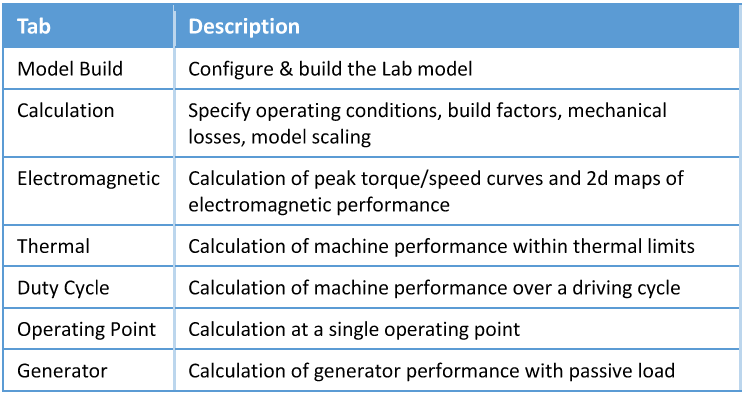

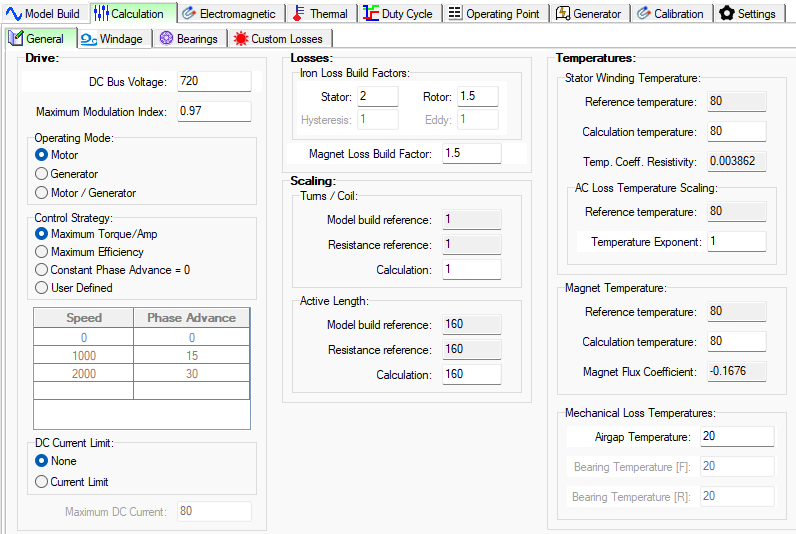

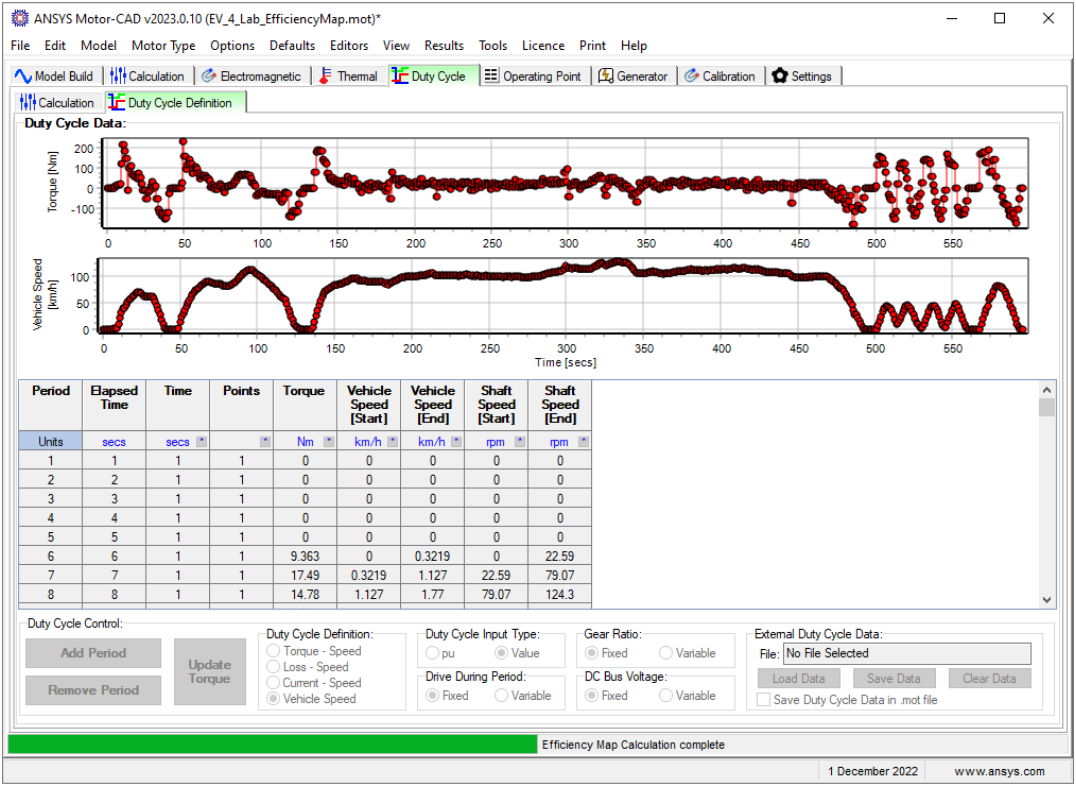

LAB - MOTOR PERFORMANCE EVALUATION

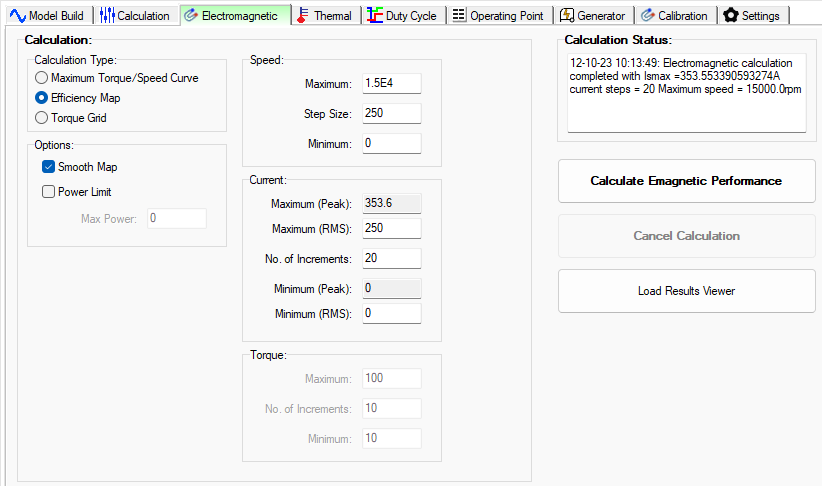

The Lab design of experiments has many tabs to cover all of the settings for the geometry creation, material selection, thermal settings, conditions, solver types, solution models, coupling settings, etc.

Lab Model

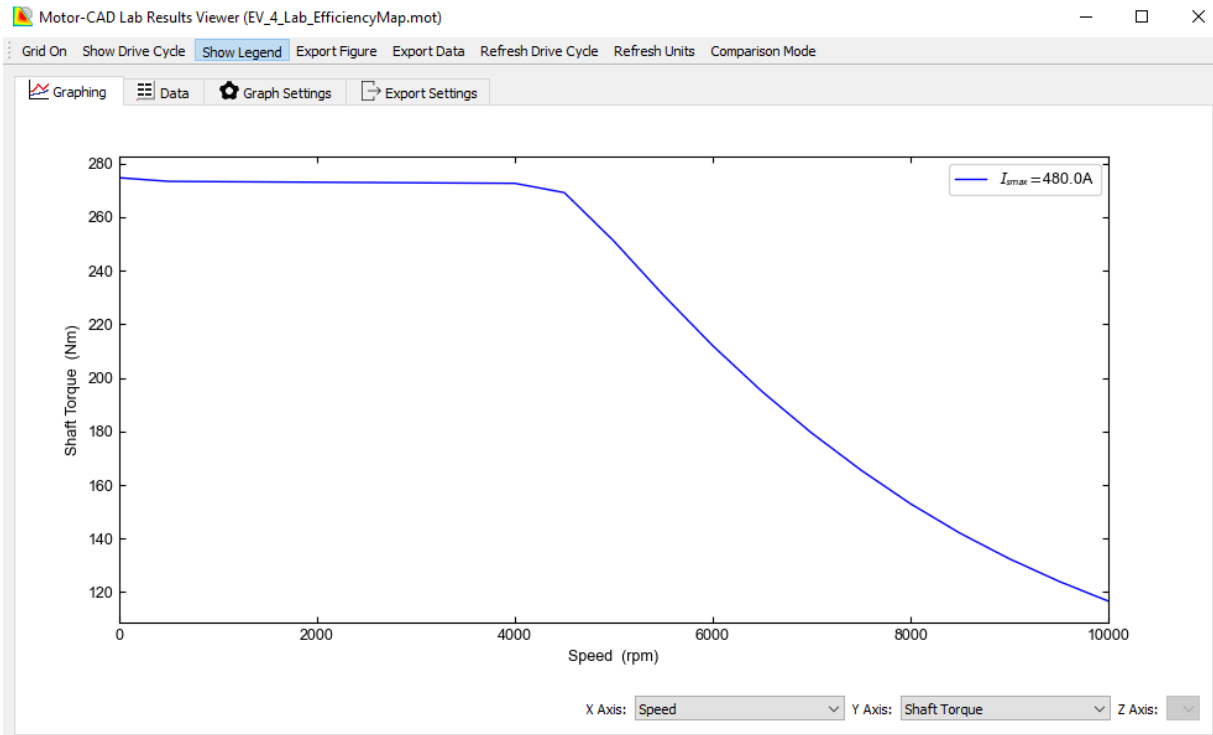

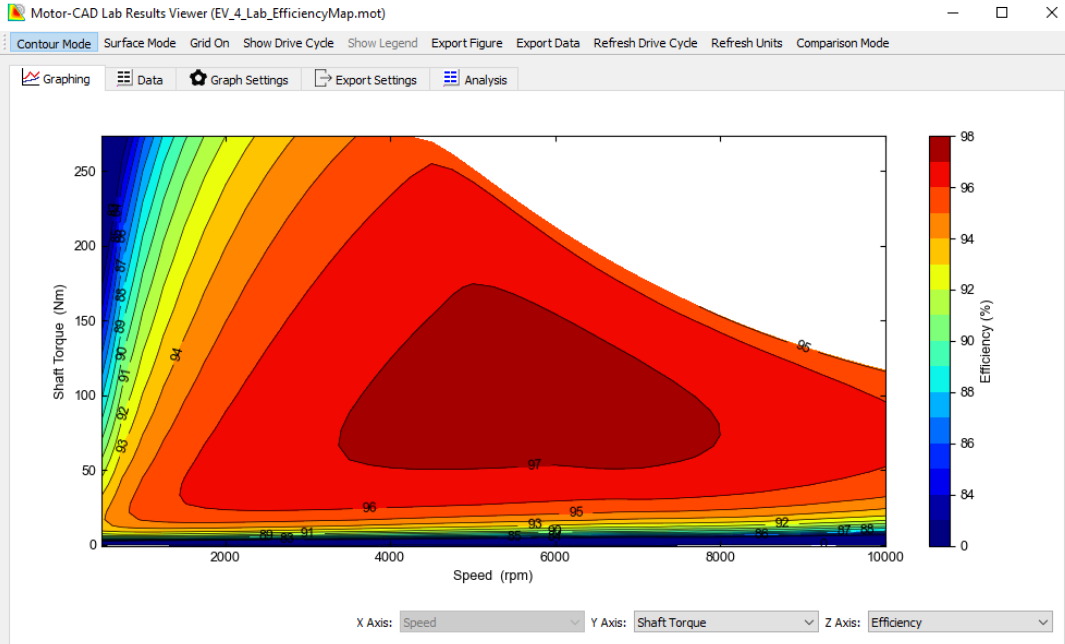

Motor-CAD’s Lab module allows us to quickly and accurately calculate the machine

performance over the full operational envelope, and can be used to

•Estimate Peak Torque/Speed.

•Develop a family of Torque vs Speed Curves.

•Create efficiency maps.

•Study the thermally constrained operational envelope

•Analyze performance over complex driving cycles.

The following tabs are available in the Lab context:

Lab Analysis

The Lab module uses a hybrid model that combines the accuracy of FEA calculations with the

speed of analytic results. We first build the Lab model, performing a series of FEA simulations

to fully characterize the saturation and loss behavior of the machine. Once this model build

is complete, we use it to accurately calculate the machine performance with analytic methods.

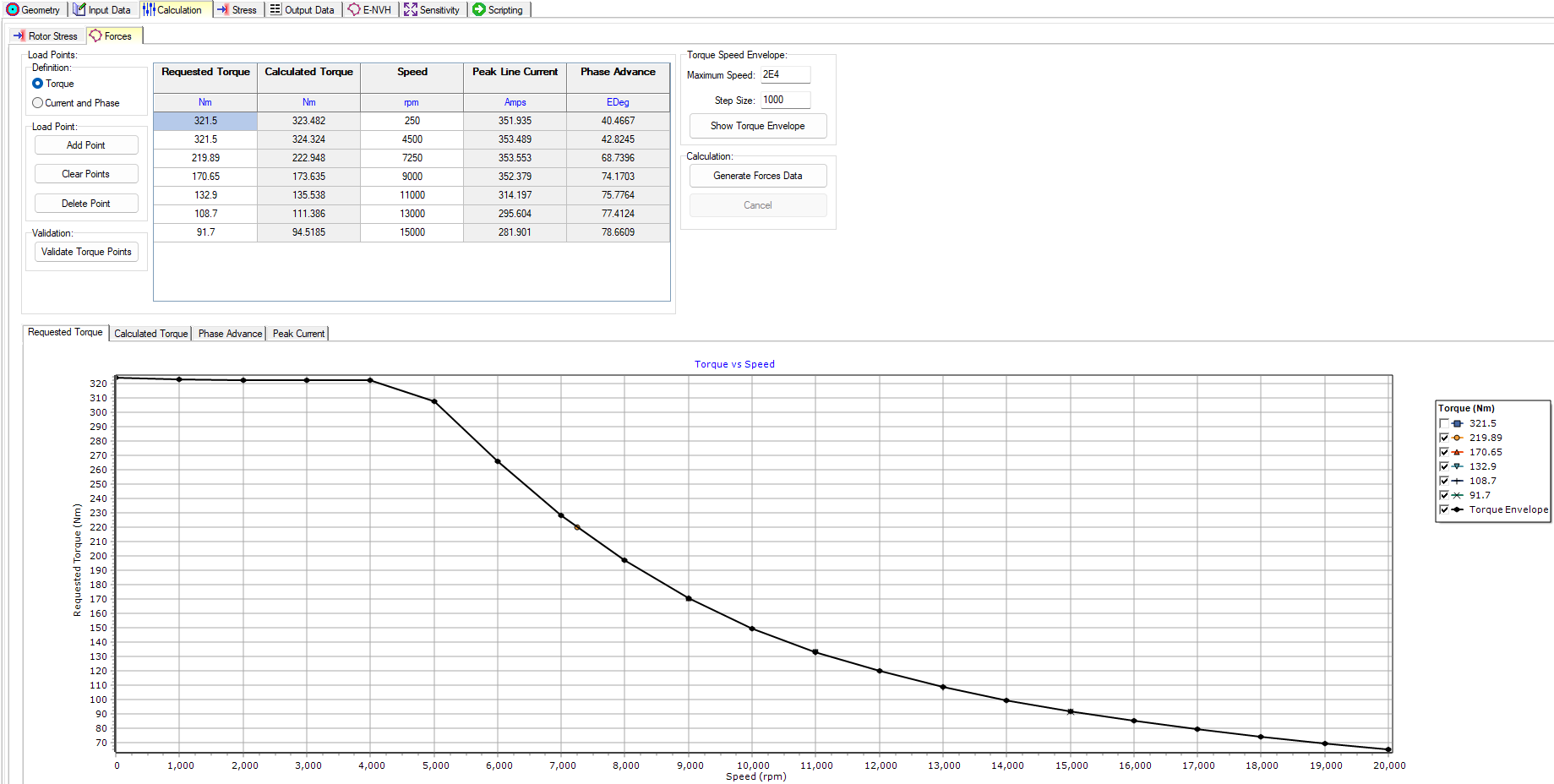

MECHANICAL MODEL

The Mechanical physics module has many tabs to cover all of the settings for the geometry creation, material selection, mechanical settings, conditions, solver types, solution models, coupling settings, etc.

Mechanical Model

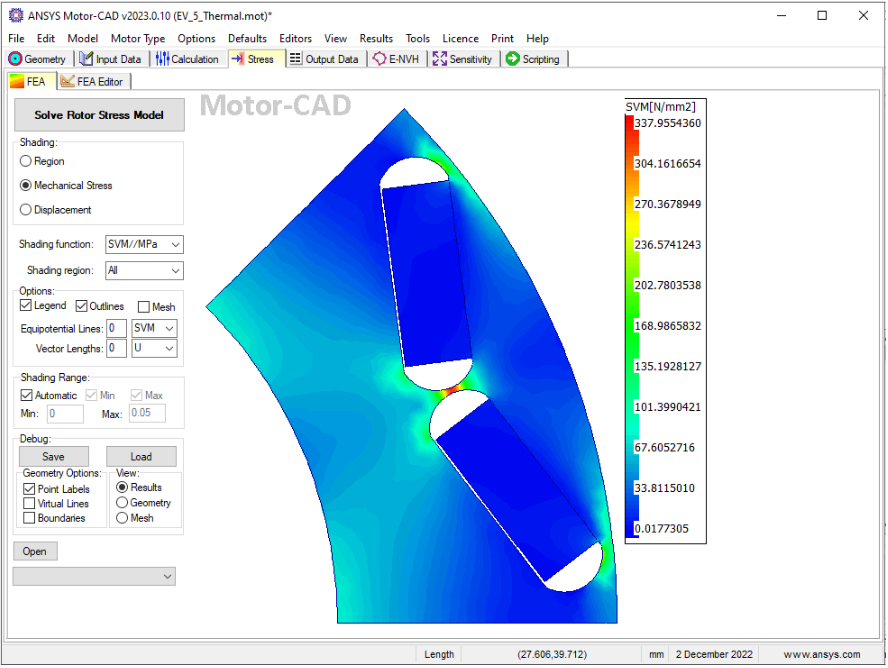

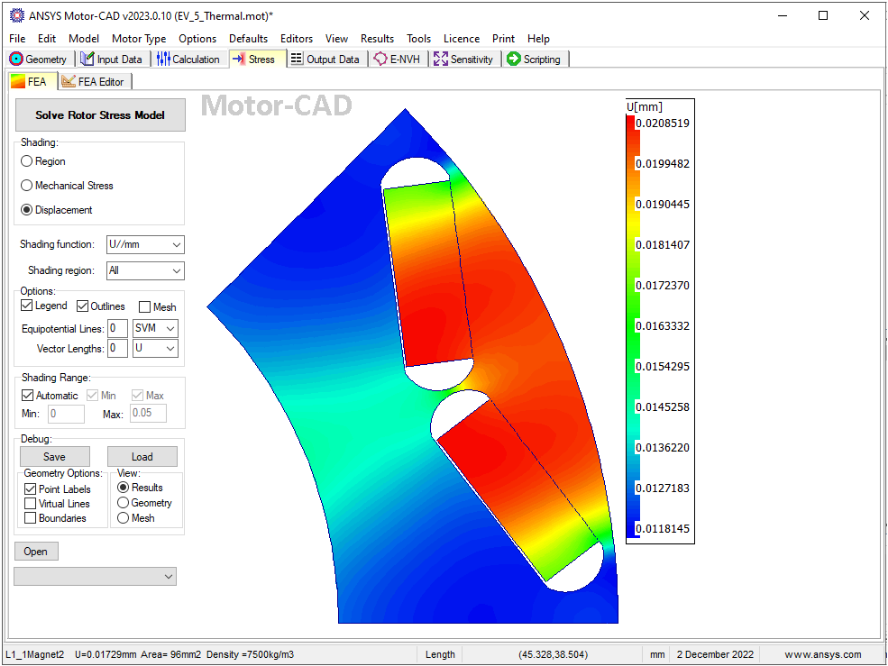

The Mechanical module in Motor-CAD uses 2D finite element simulations links to the

electromagnetic model in Motor-CAD for detailed analysis of

•Analyze stress and displacement in rotors during operation.

•NVH performance under different operating conditions.

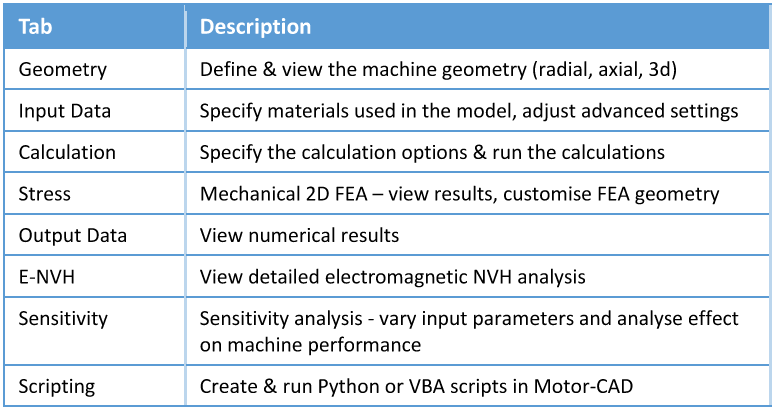

The following main tabs are available in the mechanical context:

Mechanical Model - Material

The materials tab has relevant physics parameters for the Mechanical module.

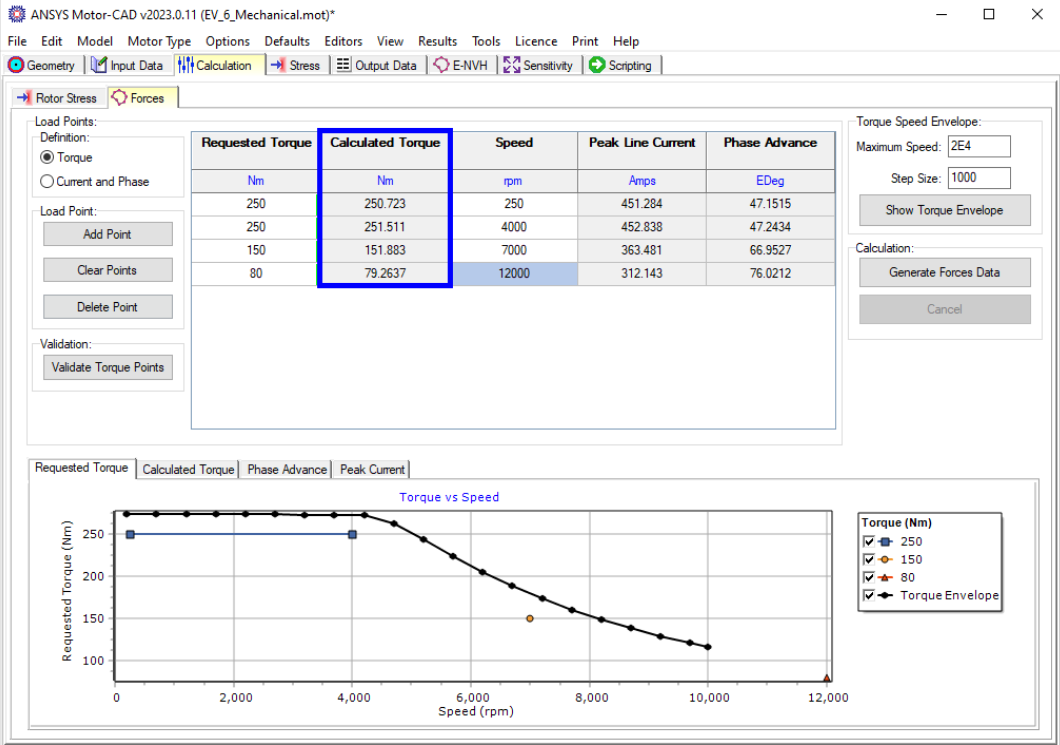

Mechanical - Calculation

The Calculation tab has relevant settings and options for the Mechanical module. Requested torque and speed is input by the user and Motor-CAD calculates the required torque. Corresponding Peak Line Current and Phase Advance calculations for the operating points are obtained as close as possible to the requested inputs.

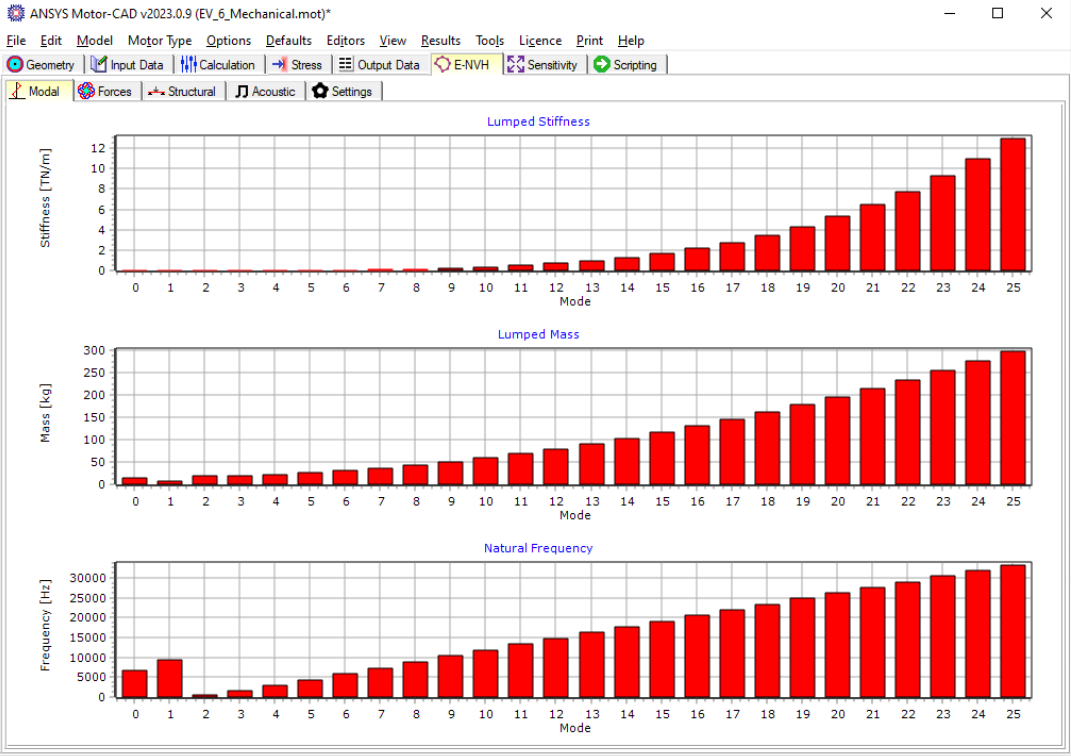

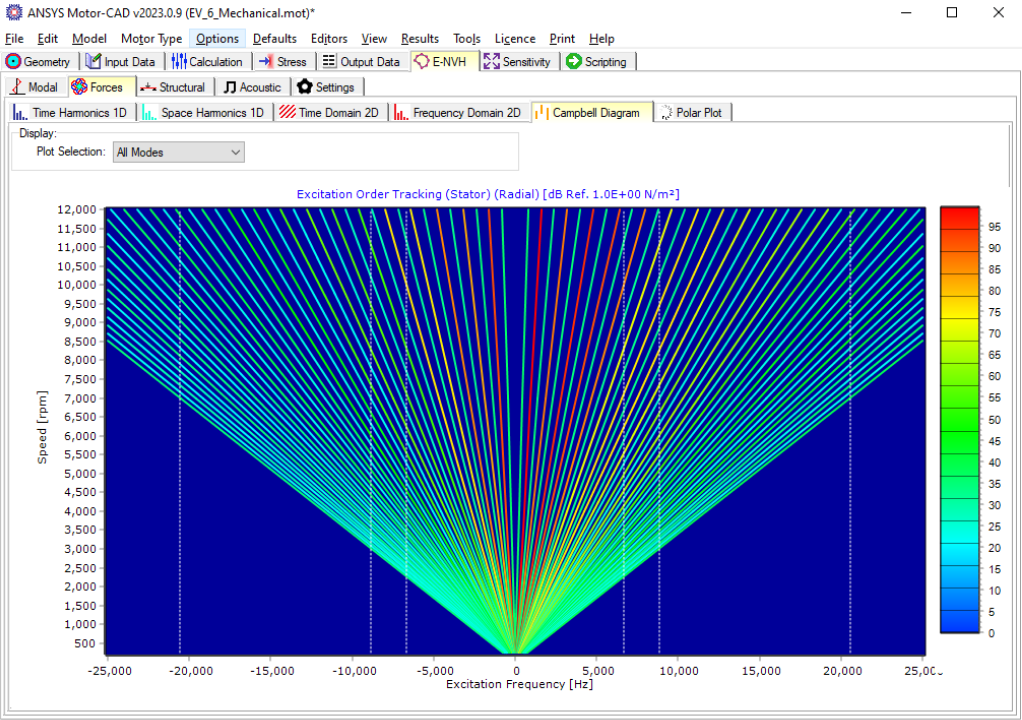

Mechanical Analysis

Motor-CAD allows engineers to consider mechanical and electromagnetic performance trade-offs during design optimization. Some of the mechanical results you can obtain in Motor-CAD are:

•Rotor stresses

•Displacements

•Stator forces from torque speed curves

•Time and space force harmonics

•Modal analysis

•Excitation tracking.

OZEN ENGINEERING INC - YOUTUBE VIDEO

ABOUT OZEN ENGINEERING INC.

Ozen Engineering is a leading provider of Ansys solutions, catering to a diverse range of industries with a specialization in electronics, semiconductor, biomedical, healthcare, aerospace and automotive applications. Our team delivers personalized solutions to optimize product design and performance by seamlessly integrating Ansys simulation into the product development process. As an elite channel partner of Ansys, we provide best-in-class software tools, consulting, training, mentoring, and technical support.

Contact us to learn about our simulation capability and request a demonstration for us to show you how we can help you with your engineering projects. Ozen Engineering Inc is an Ansys Elite Channel Partner, and we provide training to use Ansys tools, offer consulting services, and sell Ansys software packages.

Visit our website

Give us a call

Send us a message

Sep 29, 2023 12:53:08 PM