Electric motor cooling systems have advanced significantly, driven by the demand for more compact and power-dense designs in applications such as electric vehicles (EVs) and eVTOLs. Cooling strategies such as water jackets and spray cooling with nozzles are among the advanced methods used to enhance thermal management efficiency. However, simulating these methods using traditional CFD can be very time-consuming due to the high mesh counts required for complex geometries.

To address this, Smoothed Particle Hydrodynamics (SPH) offers a mesh-free alternative. Instead of discretizing the geometry with a mesh, SPH represents the fluid with particles, making it particularly effective for simulating free-surface flows and droplet-based cooling, such as oil or spray cooling.

Ansys FreeFlow is a recent software tool designed to simulate these particle-based fluid dynamics with high resolution while maintaining straightforward setup and simulation steps. In this blog, we demonstrate how to use Ansys FreeFlow to simulate oil cooling in an electric motor, in parallel with spray cooling and water jacket methods.

Project used in this blog: FreeFlowProject.zip

Ansys FreeFlow Workflow

The figure below shows the Ansys FreeFlow interface. To build a simulation, the first step is to follow the workflow tree on the left-hand side, working from top to bottom to complete the setup. Within this workflow, you can enable different modules to account for various physics.

-

-

Thermal Simulation: Activate this to model heat transfer and update fluid properties such as density, viscosity, and thermal conductivity.

-

Geometry: Import solid bodies (e.g., stator, rotor, housing) and fluid domains (inlets, outlets).

-

Simulation Settings: Define solver parameters, SPH particle resolution, rotation speed, and boundary conditions.

-

To start, right-click “Geometries” and import the structural parts of the electric motor (stator, rotor, shaft, housing) as well as the surfaces for inlets and outlets. Drag and drop the geometry into the display window to visualize it.

If your geometry has an outer wall and you want to see through it (as shown in the image on the right), enable the transparency of the shell (in this project called Housing) and adjust the transparency level.

If your geometry includes an outer wall (such as the motor housing), enable transparency for easier visualization of internal flow. In this case, the housing contains:

-

An embedded water jacket for coolant circulation.

-

Drilled endcaps with oil nozzles directed at the end windings.

The cooling system has:

-

Inlet: water/oil jacket entrance.

-

Outlets: one at the end of the water jacket, and two at the housing’s bottom to drain oil.

The red arrow indicates the inlet, and the blue arrows indicate the outlets of the system.

-

Inlet surface area: 108.1 mm²

-

Flow rate assumption: 10 L/min of oil is supplied to the system

To calculate the inlet velocity, the following equations are used:

Inlet Flow Velocity

v = Q / A

Q = 10 L/min A = 108.1016464 mm²

v = (1.667 × 10⁻⁴) / (1.0810 × 10⁻⁴) ≈ 1.54 m/s.

Thus, an inlet velocity of 1.54 m/s is applied. Oil properties are defined using ATF (Automatic Transmission Fluid) values for density and viscosity.

Rotor Rotation

To simulate cooling under operating conditions, a 1000 rpm clockwise rotation is applied to the:

1. Shaft

2. Bearings

3. Rotor core

4. Permanent magnets

This accounts for the centrifugal effects of rotating oil and the interaction between spray jets and moving rotor surfaces.

SPH Model Settings

-

Kernel size: 0.00125 m (smaller kernel → higher accuracy but longer simulation).

-

Artificial sound speed: 100 m/s (≈ 10× maximum fluid velocity, ensuring numerical stability).

-

Time step: 0.01 s.

-

Total simulated time: 8 s.

-

SPH particles generated: 664,385.

With these settings, the simulation required ~4 hours of runtime.

Post-Processing Results

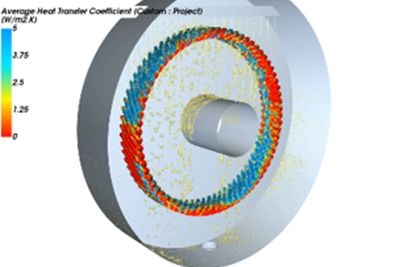

An Eulerian reconstruction is used to visualize the oil flow as a continuous field.

Spray Effect: Oil exits the nozzles with high velocity due to the small diameter, producing a spray jet that impinges directly on the end windings.

Velocity Distribution:

-

At nozzle exit: ~1.5 m/s.

-

In upward channel flow: velocity drops to ~1.0 m/s.

Transient Behavior:

-

Within the first second, nozzles start spraying oil.

After channels fill, pressure buildup enhances the spray effect, improving convective heat transfer at the windings.

Alternative Cooling Method: Shaft Jet Cooling

Another advanced method is shaft jet cooling, where nozzles are embedded in the shaft to spray oil radially onto the inner face of the end windings. This method reduces end-winding hotspot temperatures and is often combined with water jackets for hybrid cooling strategies.

Multiphysics Coupling

Ansys FreeFlow can be coupled with other Ansys solvers to extend simulation capabilities beyond fluid dynamics.

-

One-way thermal coupling: Heat transfer coefficients (HTCs) calculated in FreeFlow can be exported directly into Ansys Mechanical for advanced thermal analysis.

-

Two-way thermal–structural coupling: In this setup, FreeFlow sends SPH-calculated fluid forces to Ansys Mechanical, which computes structural deformations and then transfers the updated displacements back into FreeFlow. This allows engineers to capture fluid–structure interaction (FSI) with high fidelity.

-

Two-way coupling with Ansys Motion: This enables the simulation of complex, nested, or chained motions of moving parts, while also accounting for stress and deformation in flexible bodies.

Such multiphysics workflows make it possible to evaluate thermal, structural, and motion effects simultaneously, providing a more realistic assessment of electric motor cooling performance under real operating conditions.

Conclusion

Efficient cooling is critical for achieving high power density and reliability in modern electric motors used in EV and eVTOL applications. Traditional CFD approaches provide accuracy but are often limited by meshing complexity and high computational cost, especially for oil and spray-based cooling. By leveraging Smoothed Particle Hydrodynamics (SPH) in Ansys FreeFlow, engineers can simulate complex multiphase and droplet-driven cooling processes with reduced setup effort and robust accuracy. This enables faster design iterations, clearer insights into fluid–structure interaction, and better optimization of advanced cooling topologies such as water jackets, spray nozzles, and shaft jet cooling.

Related blogs: Getting Started with Ansys FreeFlow: Modeling a Stirred Tank

How to Simulate Electric Motor Temperature Using Ansys Motor-CAD and Icepak

Modeling Liquid Cooling for Inverters with Ansys IcePak AEDT

Ozen Engineering Expertise

Ozen Engineering Inc. leverages its extensive consulting expertise in CFD, FEA, optics, photonics, and electromagnetic simulations to achieve exceptional results across various engineering projects, addressing complex challenges such as antenna design, signal integrity, electromagnetic interference (EMI), and electric motor analysis using Ansys software.

We offer support, mentoring, and consulting services to enhance the performance and reliability of your electronics systems. Trust our proven track record to accelerate projects, optimize performance, and deliver high-quality, cost-effective results. For more information, please visit https://ozeninc.com.

If you want to learn more about our consulting services, please visit: https://www.ozeninc.com/consulting/

CFD: https://www.ozeninc.com/consulting/cfd-consulting/

FEA: https://www.ozeninc.com/consulting/fea-consulting/

Optics: https://www.ozeninc.com/consulting/optics-photonics/

Photonics: https://www.ozeninc.com/consulting/optics-photonics/

Electromagnetic Simulations: https://www.ozeninc.com/consulting/electromagnetic-consulting/

Thermal Analysis & Electronics Cooling: https://www.ozeninc.com/consulting/thermal-engineering-electronics-cooling/

Aug 22, 2025 1:58:58 PM